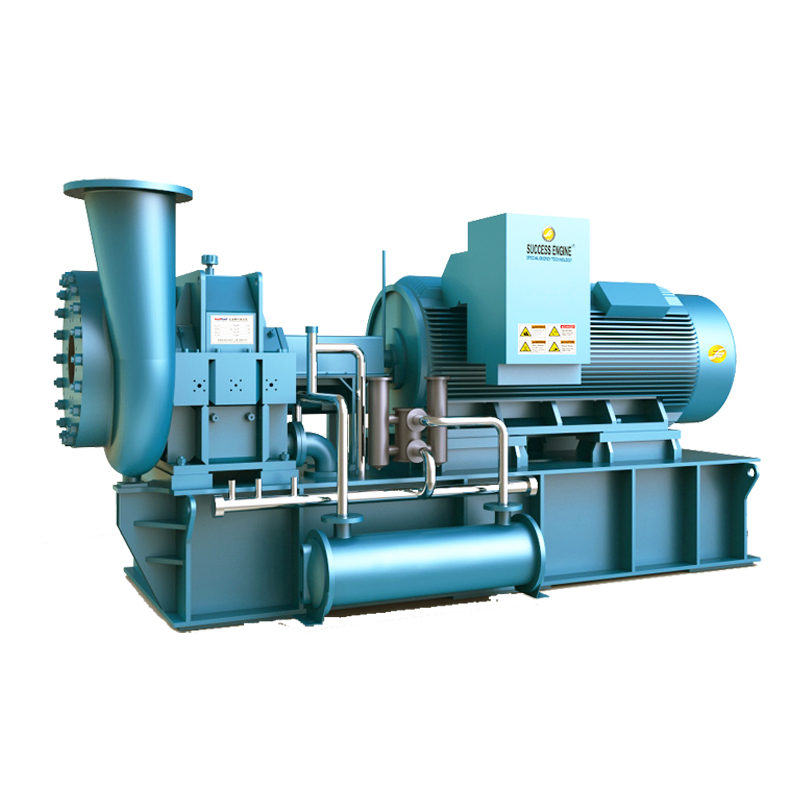

Centrifugal Vacuum Pump

Centrifugal Vacuum Pump (big vacuum system)

Centrifugal vacuum pump: air volume: 60 ~ 1000 m3/min, vacuum degree: -40 ~ 80 kPa

SUCCESS ENGINE centrifugal vacuum pump is designed for high-flow vacuuming industries such as papermaking, chemical industry, and mining. It is manufactured and tested in accordance with the standards of military nuclear power quality assurance system. The impeller is made of aviation-grade high-strength alloy materials, which can be used for 300,000 hours without maintenance. (about 35 years), the control and drive system adopts frequency conversion and high-efficiency and energy-saving motors, which are intelligent, energy-saving and efficient, and are suitable for long-term stable operation in harsh environments such as high temperature and high humidity.

—Energy-saving tool for large-flow vacuum systems in papermaking:

Provide customized design according to user’s paper machine vacuum system, enables the equipment always working in energy-efficiency area, which can save 30-60% energy and 100% water for the papermaking vacuum system. Through the waste heat recovery system, the level of comprehensive energy utilization will be further improved. The investment recovery period is 8-18 months. One unit 500kW centrifugal vacuum pump can at least completely replace the water ring vacuum pump with a total power of 710kW. Each production line can save more than one million China Yuan in electricity per year.

Saving money is making money. After adopting our company's vacuum pump instead of its old water ring pump, one listed papermaking enterprise realized energy saving of 50% and increased production by 20% under the condition that other parts of the paper machine remained unchanged. Our vacuum pump has created the value of 100 million China Yuan every year for this papermaking company.

No need for grid expansion and space saving. With frequency conversion starting, and there is no impact on the power network. Compared with traditional vacuum systems, this equipment saves more than half of space.

Centrifugal Vacuum Pump Energy-Saving Data

(The equipment works according to 24 hours, 300 days per year, and the electricity fee is calculated at 0.7 Yuan/kWh.)

|

Installed Power(KW) |

500 |

1000 |

1500 |

2000 |

2500 |

3000 |

|

|

Water ring Pump Efficiency |

Energy Saving |

Saving electricity costs is equivalent to getting net profit (10,000 Yuan/Year) |

|||||

|

30% |

60% |

151.2 |

302.4 |

453.6 |

604.8 |

756 |

907.2 |

|

33% |

56% |

141.12 |

282.24 |

423.36 |

564.48 |

705.6 |

846.72 |

|

36% |

52% |

131.04 |

262.08 |

393.12 |

524.16 |

655.2 |

786.24 |

|

39% |

48% |

120.96 |

241.92 |

362.88 |

483.84 |

604.8 |

725.76 |

|

42% |

344% |

110.88 |

221.76 |

332.64 |

443.53 |

554.4 |

655.28 |

|

45% |

40% |

100.8 |

201.6 |

302.4 |

403.2 |

504 |

604.8 |

|

48% |

36% |

90.72 |

181.44 |

272.16 |

362.88 |

453.6 |

544.32 |

|

Model |

Motor Power KW |

Shaft Power KW |

Volume Flow m3/min |

Vacuum Degree Kpa |

|

GDV75 |

75 |

69.1 |

80 |

-40~-50 |

|

GDV110 |

110 |

95.3 |

120 |

-40~-50 |

|

GDV160 |

160 |

139.1 |

175 |

-40~-50 |

|

GDV200 |

200 |

174.7 |

220 |

-40~-50 |

|

GDV250 |

250 |

217.4 |

275 |

-40~-50 |

|

GDV280 |

280 |

246.1 |

310 |

-40~-50 |

|

GDV315 |

315 |

273.9 |

345 |

-40~-50 |

|

GDV355 |

355 |

309.6 |

390 |

-40~-50 |

|

GDV400 |

400 |

349.3 |

440 |

-40~-50 |

|

GDV450 |

450 |

396.9 |

500 |

-40~-50 |

|

GDV500 |

500 |

436.7 |

550 |

-40~-50 |

|

GDV560 |

560 |

484.3 |

610 |

-40~-50 |

|

GDV650 |

650 |

560 |

700 |

-40~-50 |

|

GDV760 |

760 |

660 |

830 |

-40~-50 |

|

GDV910 |

910 |

793 |

1000 |

-40~-50 |

| Note:1.Above Design Parameters are obtained based on below conditions:

Suction Medium: Air, Relative Humidity: 65%, Suction Air Temperature: 35℃. 2. For special working conditions, the vacuum pump can be designed according to actual demands. |

||||

Centrifugal Vacuum Pump

Centrifugal vacuum pump: air volume: 60 ~ 1000 m3/min, vacuum degree: -40 ~ 80 kPa

The high-speed variable-frequency vacuum system uses advanced aero-engine technology, and refers to the military nuclear power quality assurance standards in the design, processing, manufacturing and testing. It has the advantage of superior performance, stable quality and high cost performance.

Focus on papermaking industry. The impeller adopts aviation high-temperature & high-strength alloy material, anode passivation treatment, wear-resisting, corrosion-resistant, MEKPO (Ketone Peroxide)-resistant, pulp fiber impact-resistant; it can serve 30 years without repair and maintenance.

Compared with imported turbo vacuum pump, the modification cost can be saved by more than 50% under the same installed power.

Compared with traditional vacuum pumps, energy saving: 30-50%, water saving: 100%. Through water heat recovery system, the utilization level of energy is further improved.

Unique advantage of paper machine vacuum systems

Adopt variable frequency technology, the speed and the power of vacuum pump can be adjusted with the changes of parameters of paper production line, which keep vacuum pump always working in the best operating condition.

Vacuum system is completely customized design. The most reasonable vacuum point is selected according to the operation conditions of user’s paper machine. The vacuum degree is close to the point, suction point is combined to make the high-speed centrifugal vacuum pump efficient and always run at high-efficiency zone of the pump’s and the motor’s characteristic line.

Centrifugal vacuum pump has single-stage and double-stage structures. One device can pump two different vacuum degrees, so one centrifugal vacuum pump can replace multiple water ring vacuum pumps. The device is compact and the output parameters are adjustable.

Provide complete vacuum equipment and system solutions: Including steam-water separator, cooler, filtrate pump, muffler, valve, instrument, pipe fitting and fully automatic control system for online monitoring of vacuum degree and pumping flow.

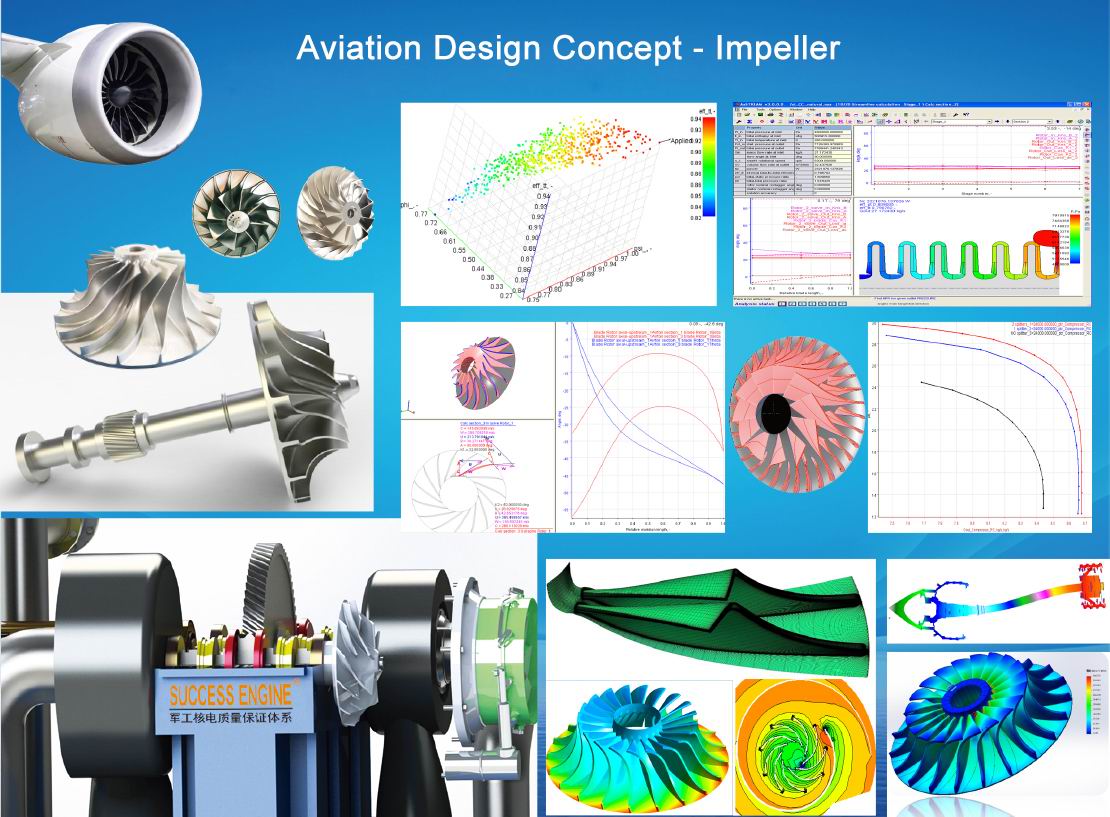

Aviation design concept – Impeller

Using finite element analysis software of NASTRAN, ANSYS, Abaqus, etc., to carry out one-dimensional geometric and thermal design, two-dimensional flow design, three-dimensional blade design and strength check of impellers and blades. Through simulation, it can be judged whether the impeller design meets the design standards of aero-engine, and the service life of the impeller can be predicted. Create high-efficiency aviation-grade impellers with the best “power energy efficiency ratio”.

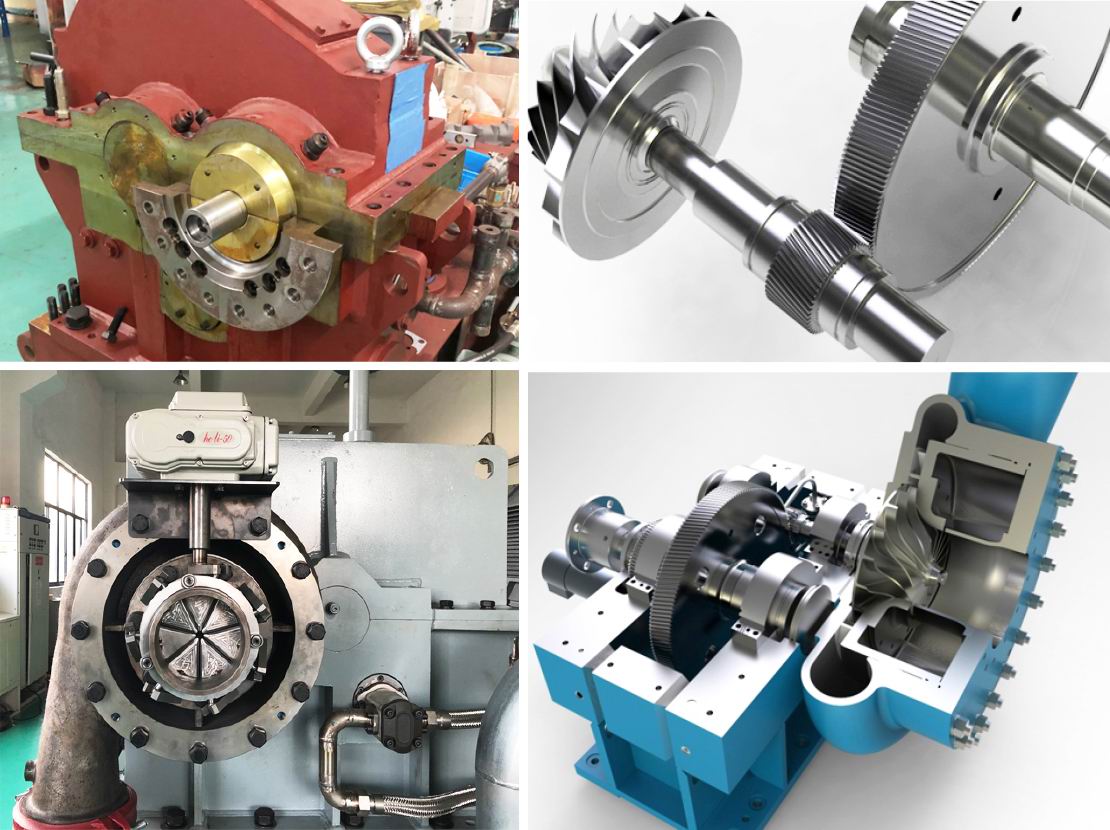

Aviation standard high speed gearbox

Horizontal split gearbox structure is used with aviation standard processing, manufacturing, debugging and inspection, with built-in high-speed forged alloy steel precision helical gears, the horizontal center divides the cylinder into upper and lower halves and connect by bolts, modular structure design is convenient for maintenance and repair.

High speed titling-pad bearing

Adopt horizontal split-type tilting-pad bearing which made by material of ISI 1040 carbon steel (inner) and babbitt alloy (surface), when the speed load changes, the bearing diagonal block is automatically centered, this automatic adjustment function can ensure the machine’s smooth operation.

Efficient removable cooler and intake air adjustment

The cooler is separated from the gearbox, and the lubrication system is perfectly separated from the compressed air, ensuring that the compressed air is 100% clean and oil-free. Removable cooler, tube bundles is precisely matched with the finished shell, which can effectively improve the heat exchange rate between compressed air and water and reduce the consumption of cooling water.

By adjusting the installation angle of inlet guide vane of the impeller, the pre-rotation of airflow can be adjusted within a range of 70-105%.

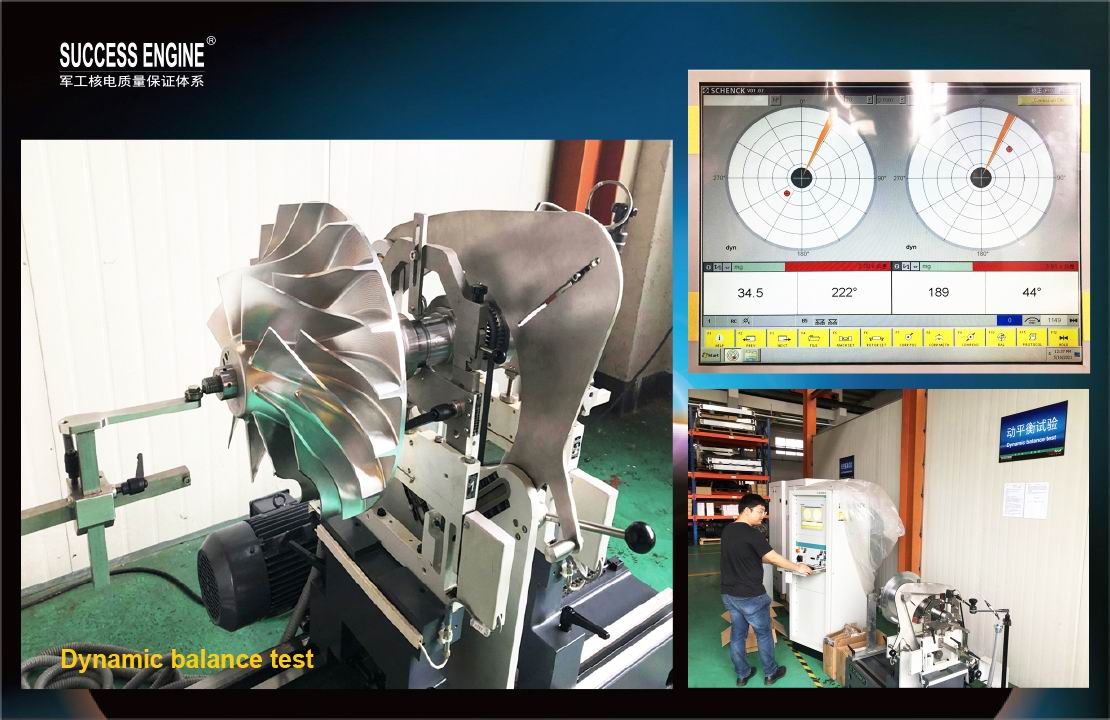

Impeller dynamic balance test

Using advanced dynamic balance testing equipment, according to the requirements of “SUCCESS ENGINE Dynamic Balance Test Procedure”, a strict dynamic balance testing is carried out on each impeller and shaft assembly to ensure the balance and stability during high-speed operation.

Advanced large-screen PLC monitoring system

Large LCD display control screen, real-time monitoring of equipment operation, shutdown information, perfectly combined the surge control and energy saving optimization, complete automatic alarm & protection functions, advanced and mature control system, guarantee the compressor system stability and ease of operation.

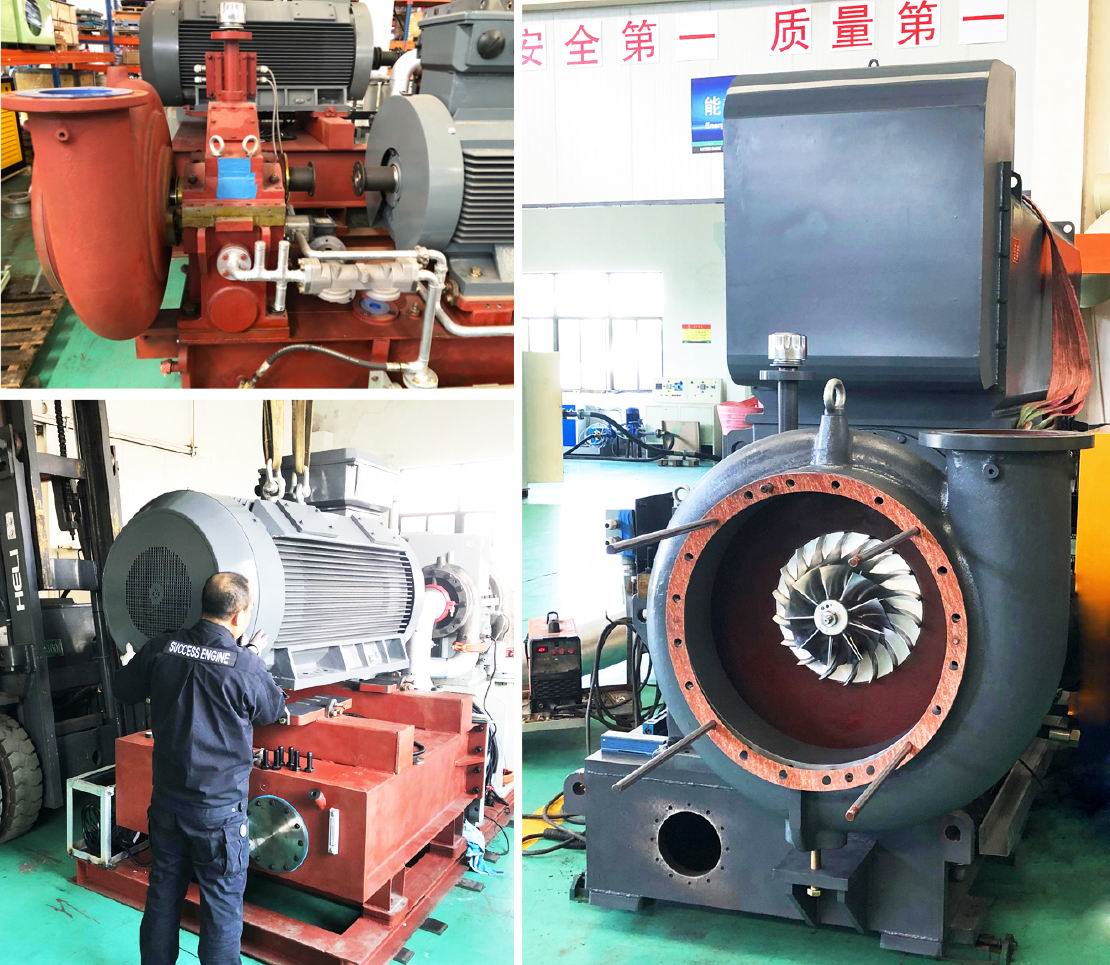

Strict manufacturing process

Design, manufacture and assembly follow strict aviation standards and military nuclear quality assurance program requirements to effectively ensure the quality and operational reliability of equipment.

Test – Evaluation - Analysis

Production Circulation Area

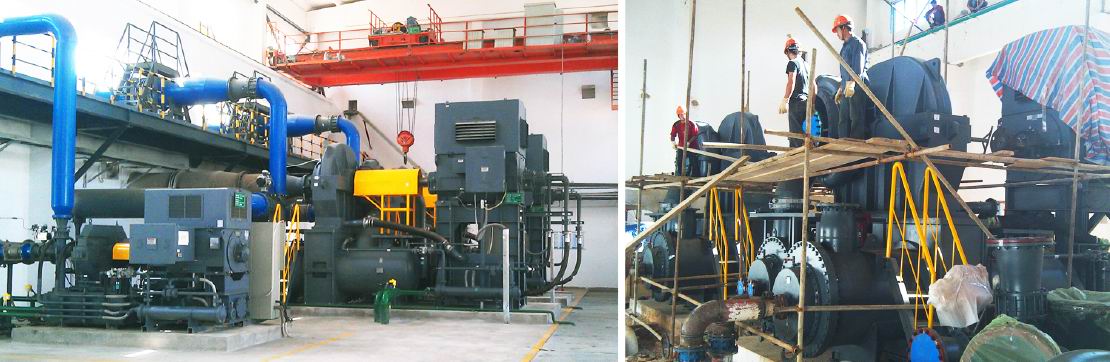

Use & Installation Site

Factory Environment