Air Suspension Blower

Air Suspension Blower

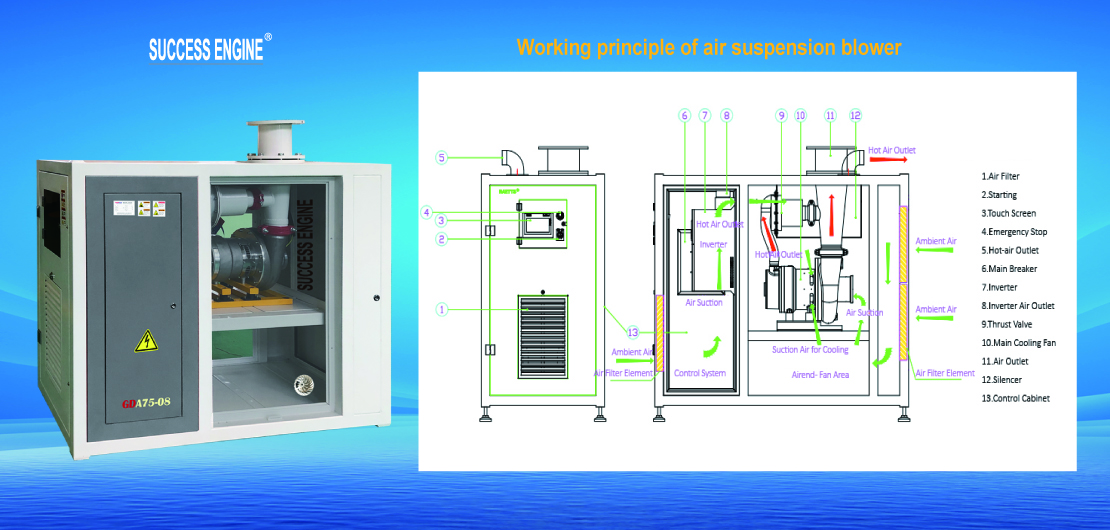

This type centrifugal blower adopts main core technologies such as air suspension bearing, permanent magnet ultra-high-speed motor and high-precision aviation-grade impeller. The unit consists of high-speed motor integrated impeller, soundproof cover, discharge taper pipe, vent valve, muffler, frequency converter, PCL controller and large-screen LCD touch screen.

The suspension bearing is different from the traditional ball bearing. There is no physical contact point between the shaft and bearing during operation, no need for lubricating oil, high efficiency, low loss, clean exhaust air, stable and durable, the number of starting can reach 100,000 times. It is an energy-saving tool in electronics, medicine, food, cement, water treatment and other industries.

Air suspension blower: flow: 17 ~ 420 m3/min, pressure: 40 ~ 100 kPa.

|

MODEL |

POWER |

PRESSURE |

AIR FLOWE |

OUTLET CONNECTION |

DIMENSION |

WEIGHT |

|

GDA22-06 |

22 |

60 |

20 |

DN150 |

1580*700*1300 |

525 |

|

GDA22-08 |

80 |

17 |

||||

|

GDA37-06 |

37 |

60 |

35 |

DN150 |

1580*700*1300 |

535 |

|

GDA37-08 |

80 |

28 |

||||

|

GDA55-04 |

55 |

40 |

74 |

DN200 |

1760*855*1550 |

750 |

|

GDA55-06 |

60 |

50 |

||||

|

GDA55-08 |

80 |

41 |

||||

|

GDA55-10 |

100 |

33 |

||||

|

GDA75-04 |

75 |

40 |

93 |

DN300 |

1760*855*1550 |

800 |

|

GDA75-06 |

60 |

65 |

DN200 |

|||

|

GDA75-08 |

80 |

53 |

||||

|

GDA75-10 |

90 |

45 |

||||

|

GDA95-06 |

95 |

60 |

81 |

DN250 |

1960*1020*1700 |

1020 |

|

GDA95-08 |

80 |

67 |

||||

|

GDA110-06 |

110 |

60 |

105 |

DN300 |

2000*1020*1710 |

1050 |

|

GDA110-08 |

80 |

85 |

DN250 |

|||

|

GDA110-10 |

100 |

65 |

||||

|

GDA150-06 |

150 |

60 |

136 |

DN250 |

2000*1020*1710 |

1090 |

|

GDA150-08 |

80 |

108 |

||||

|

GDA150-10 |

100 |

86 |

DN250 |

|||

|

GDA200-06 |

200 |

60 |

158 |

DN300 |

2000*1020*1710 |

1130 |

|

GDA200-08 |

80 |

132 |

||||

|

GDA200-10 |

100 |

103 |

||||

|

GDA225-06 |

225 |

60 |

208 |

DN400 |

2360*1300*2050 |

1590 |

|

GDA225-08 |

80 |

163 |

||||

|

GDA225-10 |

100 |

132 |

||||

|

GDA300-06 |

300 |

60 |

268 |

DN500 |

3020*1620*2050 |

2020 |

|

GDA300-08 |

80 |

213 |

DN400 |

|||

|

GDA300-10 |

100 |

170 |

||||

|

GDA375-06 |

375 |

60 |

318 |

DN500 |

3220*1760*2090 |

2050 |

|

GDA375-08 |

80 |

258 |

||||

|

GDA375-10 |

100 |

208 |

DN400 |

|||

|

GDA450-06 |

450 |

60 |

418 |

DN600 |

3520*1960*2000 |

2550 |

|

GDA450-08 |

80 |

320 |

||||

|

GDA450-10 |

100 |

258 |

DN500 |

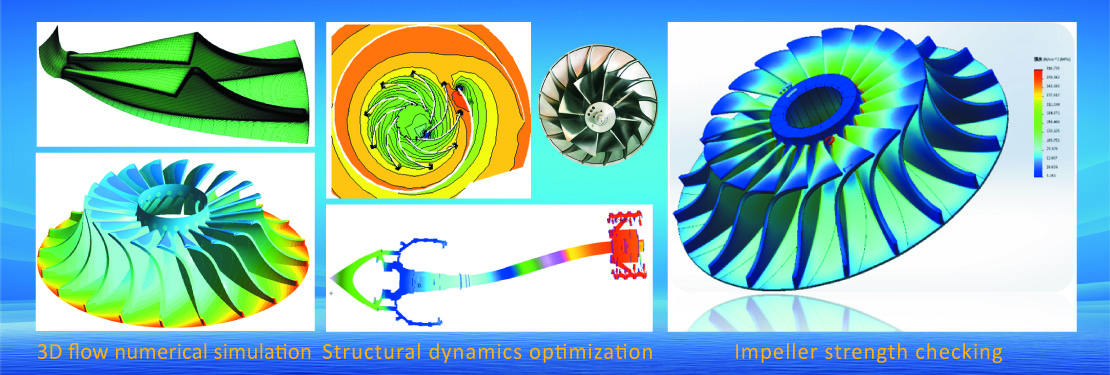

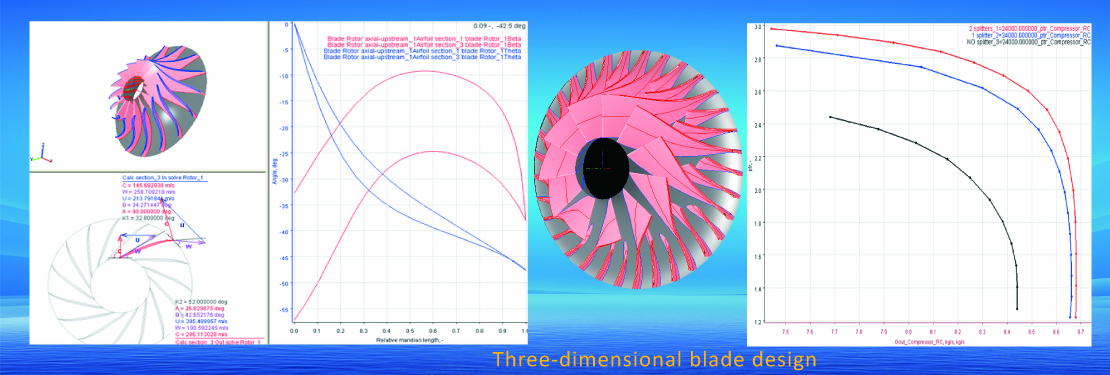

This type blower adopts the most advanced three-dimensional flow turbo technology, the impeller is made of high-strength aviation aluminum alloy, and the precision can reach 0.001mm, ensuring the high operating efficiency. Air bearing technology, 100% oil-free suspension bearing, no mechanical wear, and the service life can reach semi-permanent.

High efficiency: Compared with toots blower, the efficiency is increased by 30-40%

No pollution: no lubrication required, the discharge air is clean and free of oil and pollution

Low noise: no friction, low operating noise, meets environmental protection requirements

Less emission: Taking 100kW as an example, one unit can reduce carbon dioxide emissions by about 250 tons per year.

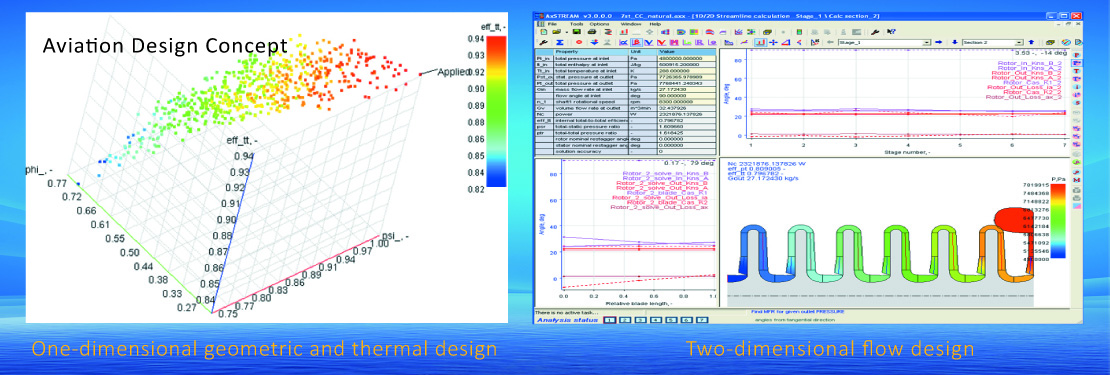

Aviation design concept – Impeller

Using finite element analysis software of NASTRAN, ANSYS, Abaqus, etc., to carry out one-dimensional geometric and thermal design, two-dimensional flow design, three-dimensional blade design and strength check of impellers and blades. Through simulation, it can be judged whether the impeller design meets the design standards of aero-engine, and the service life of the impeller can be predicted. Create high-efficiency aviation-grade impellers with the best “power energy efficiency ratio”.

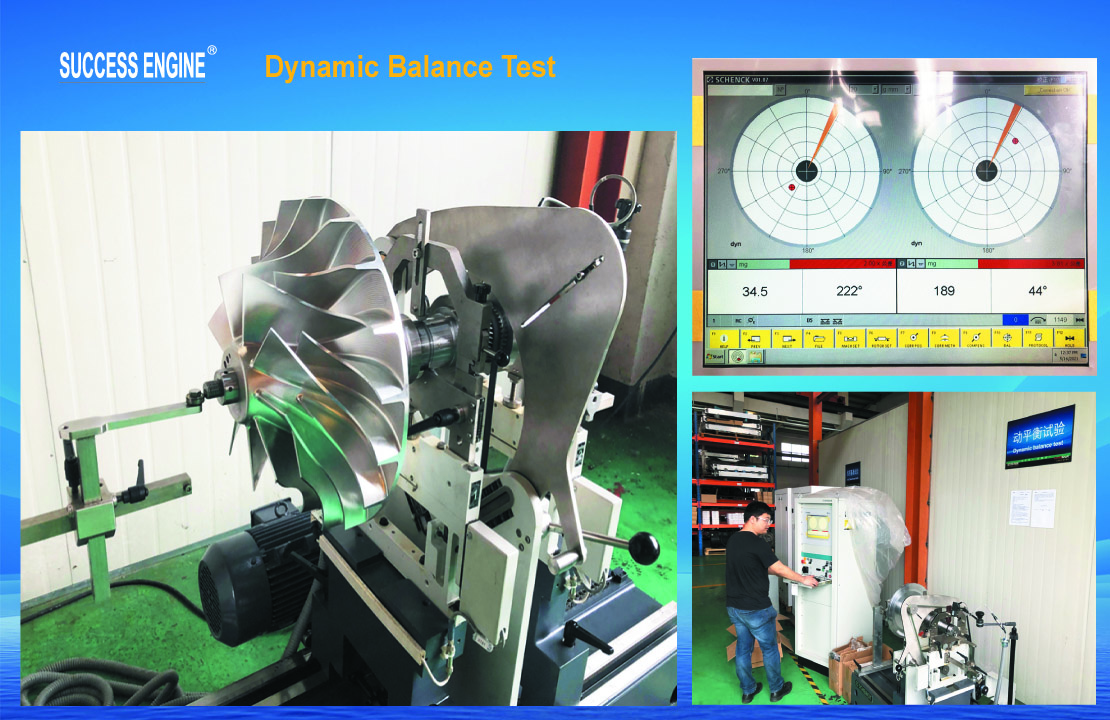

Impeller dynamic balance test

Using advanced dynamic balance testing equipment, according to the requirements of “SUCCESS ENGINE Dynamic Balance Test Procedure”, a strict dynamic balance testing is carried out on each impeller and shaft assembly to ensure the balance and stability during high-speed operation.

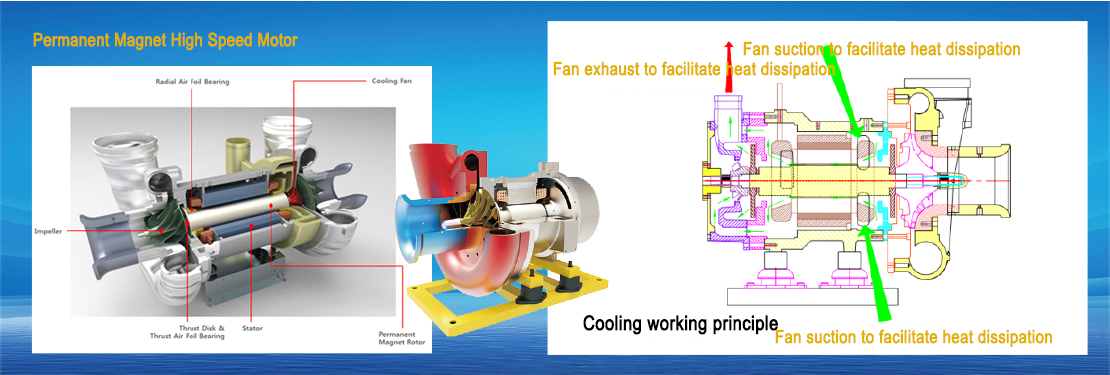

Features of high-speed permanent magnet motor

The high-speed motor can withstand low temperature storage test of -20°C for 24 hours and high temperature storage test of 55°C for 48 hours. 2pc PT100 temperature sensor and 1pc PTC thermal protector is embedded in the motor stator.

The motor cooling adopts 2-stage cooling structure system, cooling effect is more stable. The first stage is air-cooled inside the motor, and the second stage is effectively cooled in the magnetic suspension bearing assembly. The structure is simple, compact and stable.

Advanced Air Suspension Bearing Technology

Air suspension bearings mainly include radial bearings and thrust bearings. Before starting, there is physical contact between the rotary shaft and the bearing, and the rotary shaft is in a suspended state during operation, there is no physical contact point, so there is no need for lubricating oil, the energy loss is extremely low, and efficiency is high, suitable for a variety of working environments.

This technology can be applied to high-power & high-speed machinery up to 100,000 rpm. After rigorous testing, the number of starts of the bearing can reach more than 20,000 times, and the service life is more than 100,000 hours, which fully meets the design requirements.

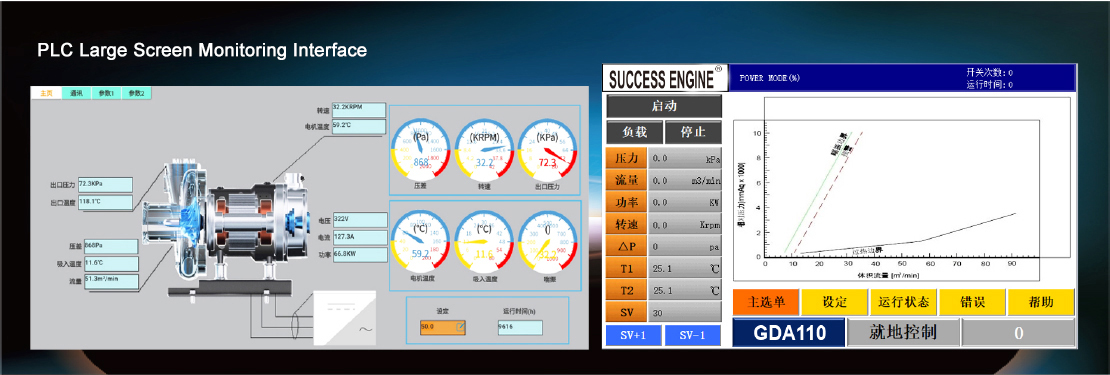

Advanced large-screen PLC monitoring system

Large LCD display control screen, real-time monitoring of equipment operation, shutdown information, perfectly combined the surge control and energy saving optimization, complete automatic alarm & protection functions, advanced and mature control system, guarantee the compressor system stability and ease of operation. Real remote control can be realized through network, wireless network mobile device, telephone network and so on.

Excellent performance and structural design

The internal integrated high-precision pressure sensor and PID adjustment system work together to make the fan run in the most energy-saving way.

The permanent magnet high-speed motor adopts the most advanced electromagnetic design technology and unique permanent magnet frequency converter.

Based on the excellent 2-stage cooling technology, the hot air is sucked in through the motor BOV system and discharged directly from the exhaust port.

The low noise, low vibration, high performance, soft-operated variable frequency speed control system is used, and the air volume and pressure can be adjusted at any time, the blower can maintain high efficiency in the entire working.