Water-Lubricant Screw Air Compressor

Water Lubricant Oil-Free Screw Air Compressor

What is water injected screw compressor?

Water injected screw compressor is next generation product which combines advantages of both Oil injected screw compressor and ordinary 2 stage oil free screw compressor.

Instead of oil, the compressor uses water for lubrication. So water itself acts as Lubricant, Sealing and Cooling function.

Like oil injected screw compressor, it is mechanically simple; on top of that, the compressed air is OIL FREE.

What is the advantage of water injected screw compressor compare to oil injected screw?

• Environmental friendly thanks to No oil lubricant usage

- No oil mist and odors

- No disposal of drain included oil

- Cut the work load and cost of compressor user to take care of disposal of drain included oil

• High quality Oil free air

What is the advantage of water injected screw compressor compare to ordinary 2 stage oil free screw?

• High efficiency and performance with energy-saving

- Water as lubricant helps to reduce pressure loss and keep high compression efficiency

• Simple structure

- 1 stage machine, No timing gear

• Outlet compressed air stays low temperature

- Isothermal compression thanks to lubricate water

• Minimum maintenance parts and low running cost

- Thanks to the simple structure

Applicable industry

Pharmaceutical Industry

Food Industry

Electronics Industry

Aerospace Industry

Chemical Industry

Textile Industry

Special tech requirement: Bottle blowing, Laboratory…

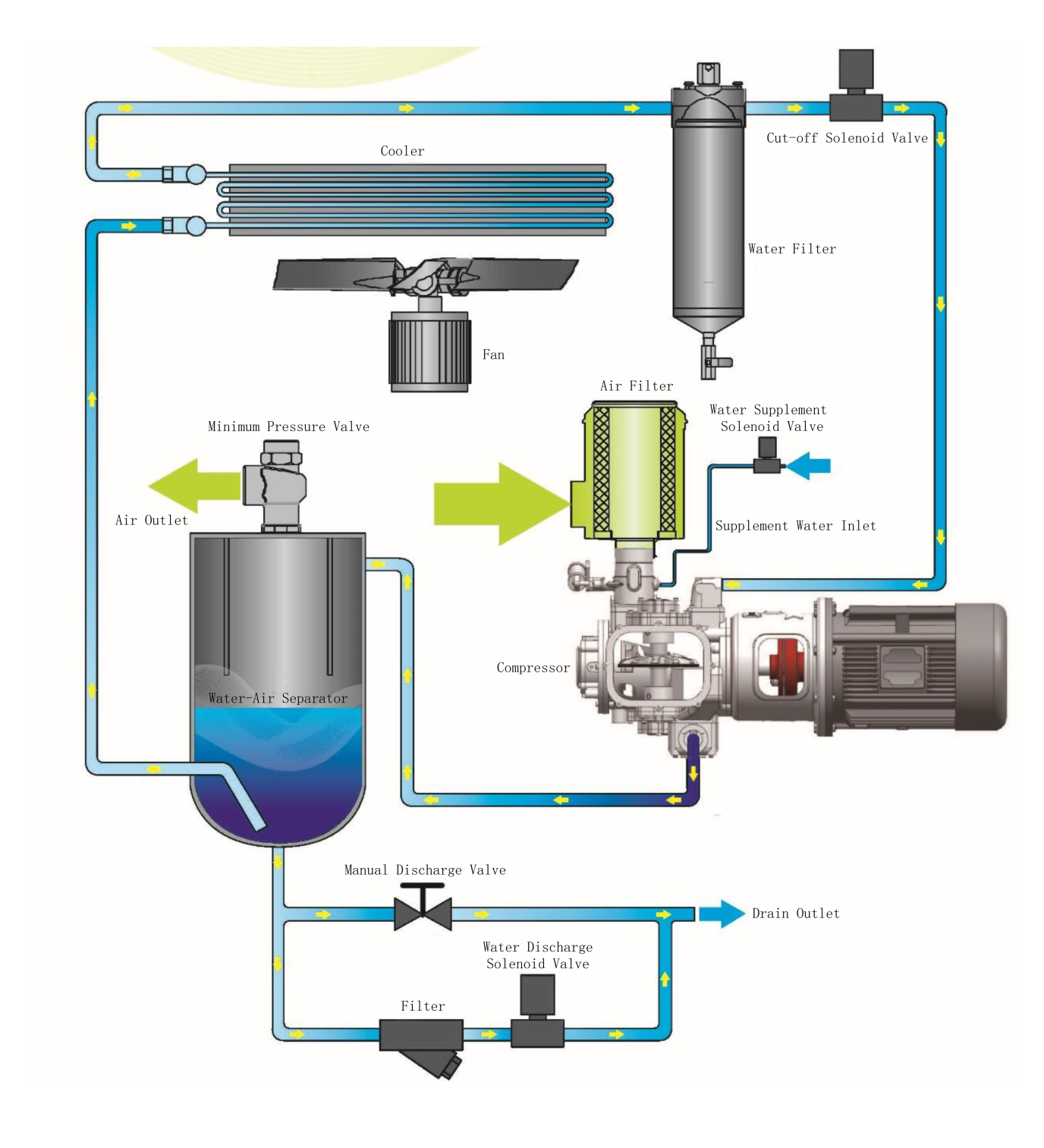

System flow

|

MODEL |

Power kw |

Pressure bar |

Air Flow m3/min |

Outlet Connection |

Weight Kg |

Dimension L×W×H mm |

|

ZW11A-3 ZW11A-4 |

11 |

3 4 |

0.9-3.1 0.7-2.5 |

Rp 1 1/2 |

630 |

1480x850x1450 |

|

ZW15A-3 ZW15A-4 |

15 |

3 4 |

1.2-4.2 2.0-3.7 |

Rp 1 1/2 |

2120 |

2200x1300x1500 |

|

ZW22A-3 ZW22A-4 |

22 |

3 4 |

2.0-6.2 1.6-5.3 |

Rp 1 1/2 |

2650 |

2500x1600x1500 |

|

ZW37A-3 ZW37A-4 |

37 |

3 4 |

3.2-10.0 2.6-8.6 |

Rp 1 1/2 |

2800 |

2500x1600x1500 |

|

ZW45A-3 ZW45A-4 |

45 |

3 4 |

4.2-13.0 3.6-10.0 |

Rp 1 1/2 |

3100 |

2800x1800x1700 |

|

ZW55A-3 ZW55A-4 |

55 |

3 4 |

5.2-17.0 4.5-13.5 |

Rp 1 1/2 |

3350 |

2800x1800x1700 |

|

ZW75A-3 ZW75A-4 |

75 |

3 4 |

7.2-23.0 6.5-20.0 |

Rp 1 1/2 |

3800 |

3100x2000x1800 |

|

ZW90A-3 ZW90A-4 |

90 |

3 4 |

9.2-27.0 7.8-24.0 |

Rp 1 1/2 |

4100 |

3100x2000x1800 |

|

ZW110A-3 ZW110A-4 |

110 |

3 4 |

11.0-33.0 9.2-28.0 |

Rp 1 1/2 |

3800 |

3100x2000x1800 |

|

ZW132A-3 ZW132A-4 |

132 |

3 4 |

15.0-43.0 11.0-36.0 |

Rp 1 1/2 |

4100 |

3100x2000x1800 |

|

ZW160A-3 ZW160A-4 |

160 |

3 4 |

18.0-50.0 15.0-42.0 |

Rp 1 1/2 |

3800 |

3100x2000x1800 |

Note: Working pressure from 1.5-4bar is available for low pressure compressor, please consult to sales.

|

MODEL |

Power |

Pressure |

Air Flow |

Outlet Connection |

Weight Kg |

Dimension L×W×H mm |

|||

|

kw |

hp |

bar |

psi |

m3/min |

cfm |

||||

|

ZW5A-7 ZW5A-8 ZW5A-10 |

5.5 |

7.5 |

7 8 10 |

101.5 116 145 |

0.7 0.5 0.3 |

24.71 17.65 10.59 |

Rp3/4 |

540 |

1060x800x1020 |

|

ZW7A-7 ZW7A-8 ZW7A-10 |

7.5 |

10 |

7 8 10 |

101.5 116 145 |

1.2 1.1 0.9 |

42.36 38.83 31.77 |

Rp3/4 |

560 |

1060x800x1020 |

|

ZW11A-7 ZW11A-8 ZW11A-10 |

11 |

15 |

7 8 10 |

101.5 116 145 |

1.6 1.5 1.4 |

56.48 52.95 49.42 |

Rp3/4 |

580 |

1060x800x1020 |

|

ZW15A-7 ZW15A-8 ZW15A-10 |

15 |

20 |

7 8 10 |

101.5 116 145 |

2.4 2.2 2.0 |

84.72 77.66 70.60 |

Rp3/4 |

620 |

1060x800x1020 |

|

ZW18A-7 ZW18A-8 ZW18A-10 |

18.5 |

25 |

7 8 10 |

101.5 116 145 |

3.1 2.8 2.5 |

109.43 98.84 88.25 |

Rp3/4 |

800 |

1760x1060x1460 |

|

ZW22A(W)-7 ZW22A(W)-8 ZW22A(W)-10 |

22 |

30 |

7 8 10 |

101.5 116 145 |

3.7 3.4 3.0 |

130.61 120.02 105.90 |

Rp1 |

860 |

1760x1060x1460 |

|

ZW30A(W)-7 ZW30A(W)-8 ZW30A(W)-10 |

30 |

40 |

7 8 10 |

101.5 116 145 |

5.2 4.7 4.3 |

183.56 165.91 151.79 |

Rp1 1/2 |

920 |

1760x1060x1460 |

|

ZW37A(W)-7 ZW37A(W)-8 ZW37A(W)-10 |

37 |

50 |

7 8 10 |

101.5 116 145 |

6.1 5.6 5.0 |

215.33 197.68 176.50 |

Rp2 |

1200 |

1760x1160x1500 |

|

ZW45A(W)-7 ZW45A(W)-8 ZW45A(W)-10 |

45 |

60 |

7 8 10 |

101.5 116 145 |

7.5 6.8 6.0 |

264.75 240.04 211.80 |

Rp2 |

1360 |

1760x1160x1500 |

|

ZW55W-7 ZW55W-8 ZW55W-10 |

55 |

75 |

7 8 10 |

101.5 116 145 |

10.0 9.0 7.8 |

353.00 317.70 275.34 |

Rp2 |

1600 |

1850x1350x1350 |

|

ZW75W-7 ZW75W-8 ZW75W-10 |

75 |

100 |

7 8 10 |

101.5 116 145 |

13.0 12.0 10.0 |

458.90 423.60 353.00 |

Rp2 |

1860 |

1850x1350x1350 |

|

ZW90W-7 ZW90W-8 ZW90W-10 |

90 |

120 |

7 8 10 |

101.5 116 145 |

15.5 14.0 12.5 |

547.15 494.20 441.25 |

Rp2 |

2300 |

1980x1450x1500 |

|

ZW110W-7 ZW110W-8 ZW110W-10 |

110 |

150 |

7 8 10 |

101.5 116 145 |

20.0 18.0 16.0 |

706.00 635.40 564.80 |

DN80 |

2800 |

2200x1850x1700 |

|

ZW132W-7 ZW132W-8 ZW132W-10 |

132 |

180 |

7 8 10 |

101.5 116 145 |

25.0 23.0 20.0 |

882.50 811.90 706.00 |

DN80 |

3100 |

2200x1850x1700 |

|

ZW160W-7 ZW160W-8 ZW160W-10 |

160 |

220 |

7 8 10 |

101.5 116 145 |

27.0 25.5 24.0 |

953.10 900.15 847.20 |

DN80 |

3300 |

2300x1900x1850 |

|

ZW185W-7 ZW185W-8 ZW185W-10 |

185 |

250 |

7 8 10 |

101.5 116 145 |

30.0 28.0 25.0 |

1059.00 988.40 882.50 |

DN80 |

3700 |

2300x2000x1850 |

|

ZW200W-7 ZW200W-8 ZW200W-10 |

200 |

270 |

7 8 10 |

101.5 116 145 |

36.0 33.0 27.0 |

1270.80 1164.90 953.10 |

DN80 |

4200 |

2500x2000x1850 |

|

ZW250W-7 ZW250W-8 ZW250W-10 |

250 |

340 |

7 8 10 |

101.5 116 145 |

43.0 41.0 38.0 |

1517.90 1447.30 1341.40 |

DN100 |

4800 |

3200x2000x2000 |

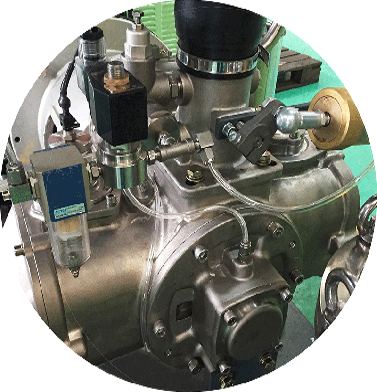

The main engine structure adopts a single screw All stainless steel compressor, the lubricating medium adopts pure water that meets the drinking water standard, and is equipped with high-performance stainless steel components. The entire compression system does not have any oil-lubricated components. Therefore, the compressed air reaches TUV CLASS 0 grade pure oil-free!

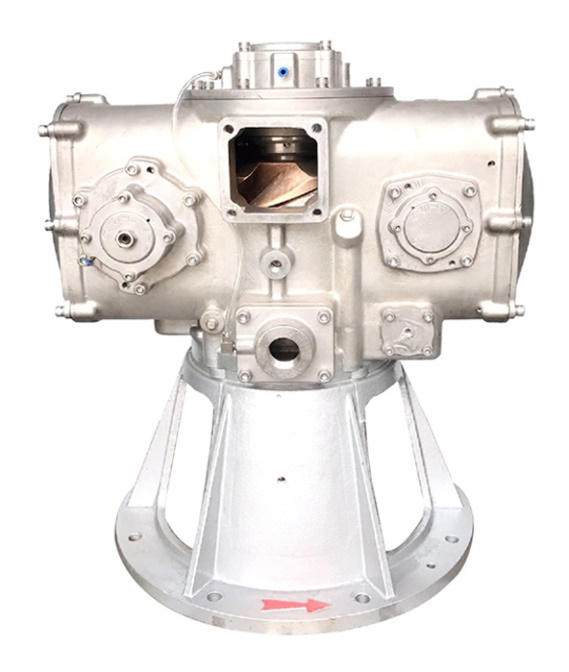

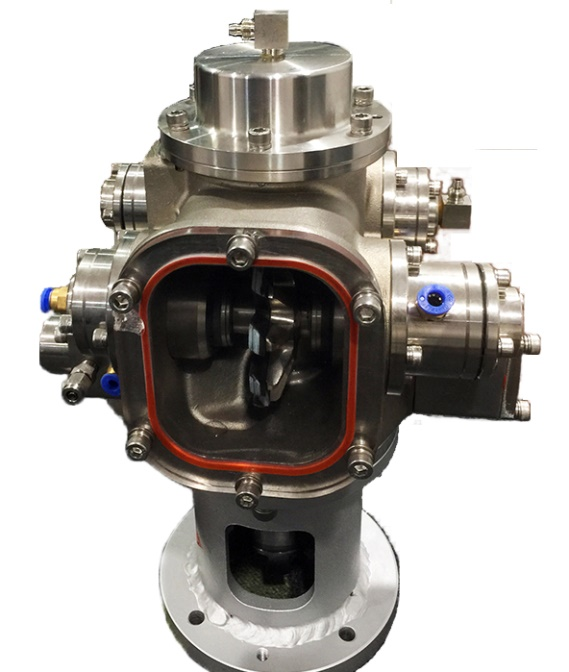

Water-lubricated Oil-free Compressor Airend

Shanghai SUCCESS ENGINE Compressor Co., Ltd. has successfully developed a airend without oil after several years of careful development and experiments. Its casing, star wheel and rotor are made of stainless steel and special alloy materials and processed by a special numerical control machine to ensure that the core components will never scale and rust when running.

|

|

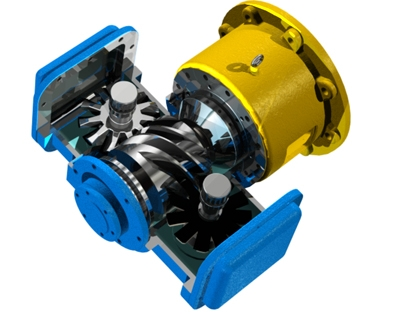

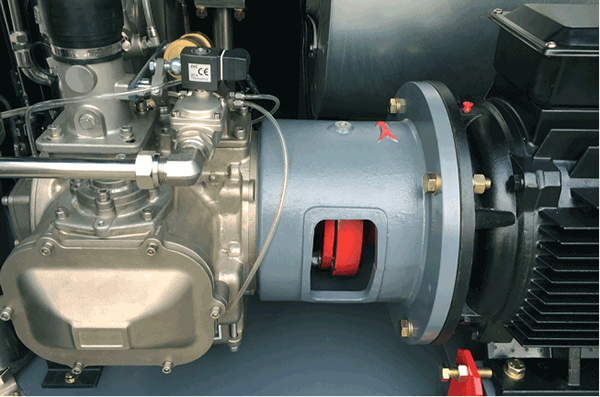

Main Rotor Structure

The main rotor adopts a single screw structure, and the screw meshes with the left and right star wheels to compress to ensure the mechanical balance and achieve the effects of low vibration and low noise under pressure.

|

|

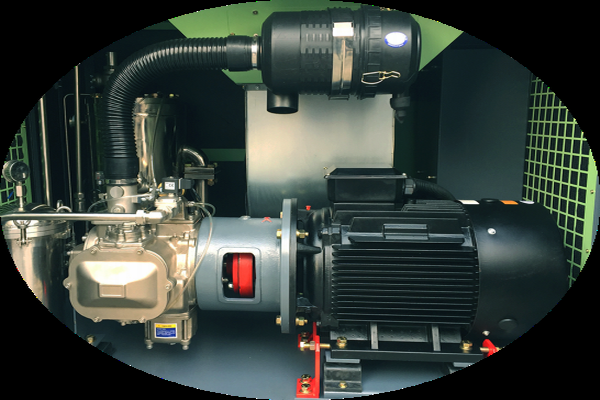

Direct-drive Electric Motor

The main airend is connected with the output shaft of electric motor through an elastic coupling, and the operating speed is less than 3000rpm, making the transmission loss almost zero.

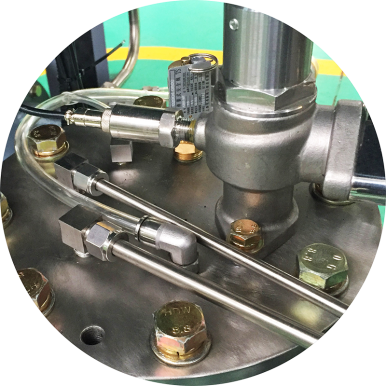

Only Need Water to lubricate

Water-lubricated compressor uses water as the sealing medium, and the operating speed and temperature are very low. There is no lubricating oil in the system, which can ensure that the discharged compressed-air is clean and oil-free.

|

|

Food Grade Material - Energy Saving and Environmental Protection

The whole machine system is composed of stainless steel components and control components that meet Food-grade Standards, including: compressor airend, separation tank, control valve, circulation pipeline, connecting piece, filter component, water level controller, water supply and drainage device, system hose and other corrosion-resistant material components to ensure the purity of the system.

|

|

|

|

|

|

Frequency Conversion Adjustment

Adopts frequency conversion speed regulation system (VSD), with stepless speed adjustment, stable air pressure and stable start-up, so as to realize the change of compressed air volume meet the change of efficiency, saving your energy.

Simple and Durable Structure

|

|

Water-lubricated oil-free air compressor realizes low-temperature compression, low-speed operation, simple structure and convenient maintenance, so that the operation and maintenance costs are greatly reduced compared with other types of oil-free air compressors.

SUCCESS ENGINE Production Workshop

User Site