Four-in-one Integrated Screw Air Compressor

What is SUCCESS ENGINE Four-in-one Integrated Screw Air Compressor

To save user’s purchase and installation costs, and based on the high reliability, high efficiency, and easy operation design principle, SUCCESS ENINE has launched the tank mounted screw compressors with dryer and 3-class air filters. This type integrated package screw air compressor not only looks more beautiful, but also easy to use and movement. Once launched, it is welcomed and recognized by many users.

Compressor Picture

(①-Screw Air Compressor ②-Air Dryer ③-Air Tank ④-Air Filter)

Advantages of SUCCESS ENGINE Four-in-one Integrated Screw Air Compressor

1)The air quality was significantly optimized after the integrated system, and so that the air can meet different industry’s needs.

2)Space saving, compact compressed air system.

3)Complete system, no additional drying system, no pipelines installation costs.

4)Easy to use, flexible and lightweight, users can get high-quality compressed air just after power-supply.

5)The integrated electric cabinet can control the compression system and the drying system at the same time, it has greatly improved the compressor system’s efficiency.

6)It can be modularly installed in the production line to improve the integrity of the production system.

7)Beautiful appearance, reliable performance and economic superiority.

|

MODEL |

POWER |

PRESSURE |

AIR FLOW |

Tank |

Air Dryer |

Air filters |

NOISE LEVEL dB(A) |

OUTLET CONNECTION |

WEIGHT KG |

DIMENSION L×W×H mm |

|||

|

kw |

hp |

bar |

psi |

m3/min |

cfm |

||||||||

|

SEC4A-7/T SEC4A-8/T SEC4A-10/T SEC4A-13/T |

4 |

5.5 |

7 8 10 13 |

101.5 116 145 188.5 |

0.5 0.5 0.4 0.25 |

17.65 17.65 14.12 8.825 |

250Litre |

DA-08 (0.8m3/min) |

SF18-P/A/F (1.8m3/min) |

60 |

Rp 3/4 |

250 |

1426x620x1420 |

|

SEC5A-7/T SEC5A-8/T SEC5A-10/T SEC5A-13/T |

5.5 |

7.5 |

7 8 10 13 |

101.5 116 145 188.5 |

0.8 0.8 0.63 0.5 |

28.24 28.24 22.24 17.65 |

250Litre |

DA-08 (0.8m3/min) |

SF18-P/A/F (1.8m3/min) |

60 |

Rp 3/4 |

270 |

1426x620x1420 |

|

SEC7A-7/T SEC7A-8/T SEC7A-10/T SEC7A-13/T |

7.5 |

10 |

7 8 10 13 |

101.5 116 145 188.5 |

1.15 1.15 1.0 0.79 |

40.60 40.60 35.30 27.89 |

250Litre |

DA-14 (1.4m3/min) |

SF18-P/A/F (1.8m3/min) |

62 |

Rp 3/4 |

290 |

1426x620x1420 |

|

SEC11A-7/T SEC11A-8/T SEC11A-10/T SEC11A-13/T |

11 |

15 |

7 8 10 13 |

101.5 116 145 188.5 |

1.80 1.80 1.50 1.20 |

63.54 63.54 52.95 42.36 |

250Litre |

DA-18 (1.8m3/min) |

SF18-P/A/F (1.8m3/min) |

66 |

Rp 3/4 |

330 |

1426x620x1420 |

|

◎Excellent compressor airendAirend adopt European compressor technology, reform the mesh and seal of the bottom line & improve the length: diameter ratio of the double screw rotors, increase the efficient sectional area. Running is more stable. |

|

◎Specific screw compressor motorOptimized design motor, with all designs in conformity with the international standard. Wide range of application of voltage to make compressors more economical in energy consumption and more constant in air supply pressure. |

|

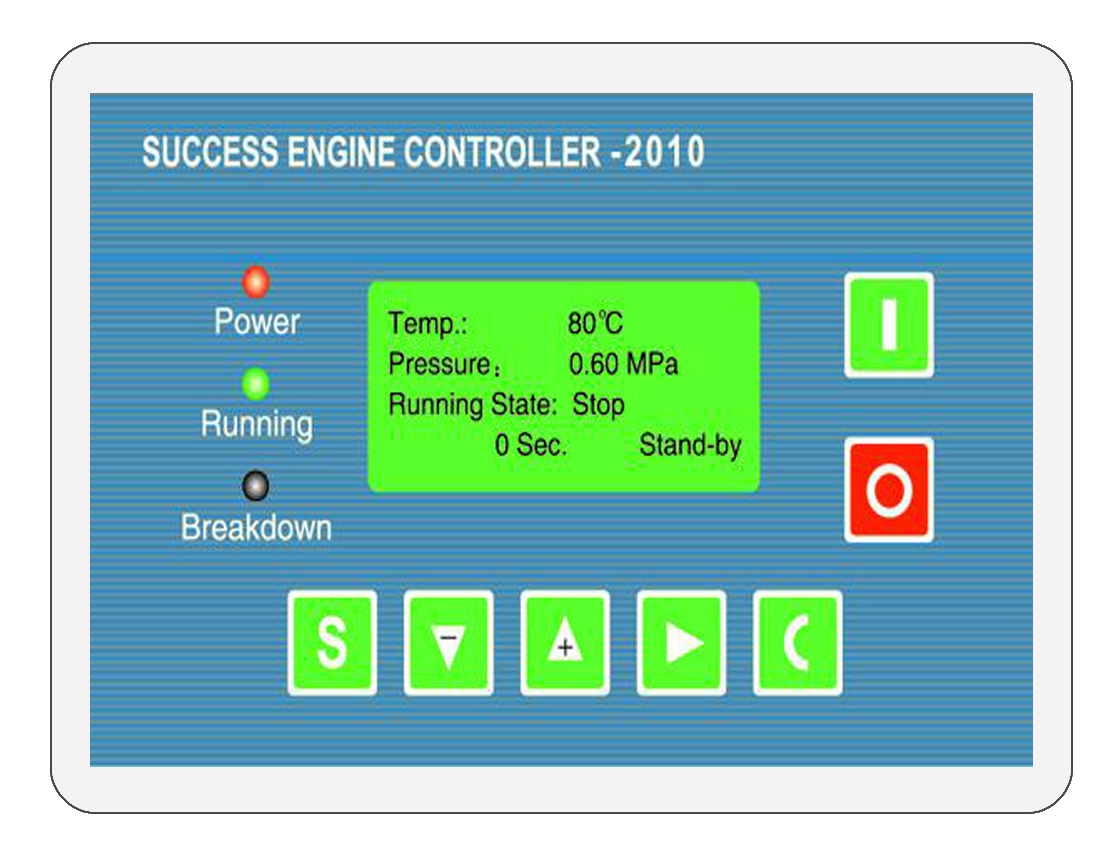

◎Control SystemFirst brand electrical components. All breakers, AC contactors, with a life of more than 20 years, which offering a long-term guarantee for safe use. |

|

◎PLC intelligent control systemHuman-based user interface: Four control models, Real running stage display, Automatic alarm and protection, Specification preset and modification, History record. |

|

◎Specially designed air-cooled systemLatest type of cooling fan is matched with fan blades by special angles, which are combined into a closed cooling system structure to achieve higher heat dissipation and ensure that the air compressor is normal under high temperature conditions in summer, Reduce the cooling system energy consumption and the noise. |

|

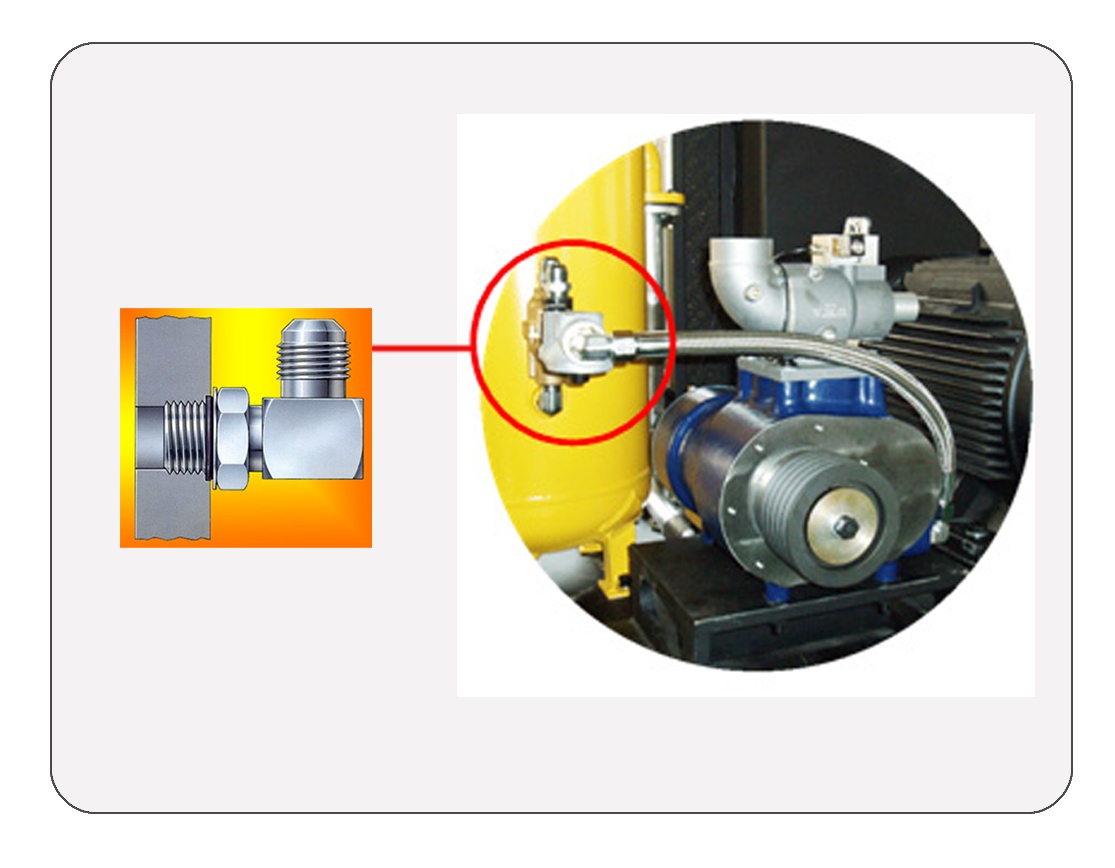

◎Leak-proof designSealing-up connection parts: Adopt the “SAE” connecting parts which conform to the standard of “America Auto Industry Association”, decrease the leakage, prolong the useful life, remove the boring problem with oil and air leakage. Pipeline parts: Both the oil and air pipelines are inside and outside double protection, heat-resisting, pressure-resisting, long duration. |

|

◎High-efficiency Filter System◆ High-efficiency air filter, filter the air of dust and impurities, filtration come to 98.5% ◆ Branded oil filter, filter the air of oil, guarantee the long time use life of airend ◆Oil-Air Separator element, high-efficient separation, oil contact less than 2ppm |