VSD-VFD Screw Air Compressor

Description

SUCCESS ENGINE VSD series (inverter driven compressor) and YC series (permanent magnetic variable frequency compressor) is a new-conception energy-saving product. By varying the speed of the drive motor in accordance to the change of the air capacity required, it regulates the actual power accordingly and thus saves the energy effectively. By adopting the electronic inverter system and the technology of supplying the exact air capacity required and precise pressure controlling, VSD air compressor not only directly reduces energy consumption by 30% but also brings many other benefits, such as stabilizing the network pressure, eliminating the peak current on starting, etc. VSD compressor serves as the best choice for the modern industrial and mining enterprises to save energy.

Variable Speed Drive Air Compressor (SEVSD7.5KW-315KW Series)

1. Power: 10-425HP, pressure: 0.7-1.3MPa.

2. Top compressor air end, variable frequency motor, and ABB/SUCCESS ENGINE frequency converter are adopted; Air consumption change is automatically tracked and the motor speed is adjusted correspondingly; Energy consumption is reduced by 30%.

3. Variable frequency motor: Protection class of IP55, insulation class of F, service factor SF=1.2.

4. The variable frequency starting greatly reduces the impact caused by instantaneous current on the grid, this effectively extending the service life of machine.

5. The adopted PLC intelligent control system supports control mode selection, operation status display, parameter presetting and fault history query.

6. There is a MODBUS485 interface reserved for remote monitoring.

7. Type of cooling: Air cooling or water cooling.

8. Product of different working voltage and frequency can be customized, 120V, 220V, 240V, 400V, 415V, 440V, 460V, 575V, 50Hz and 60Hz.

Performance features

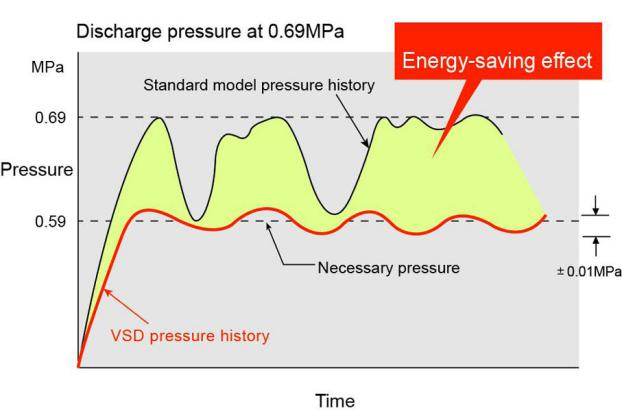

1.Stable Pressure

The variable speed air compressor adopts PID for precision speed adjustment.Changes in the air amount of the system will be automatically tracked.The compressor will supply air at a constant pressure,which is the preset desired pressure plus or minus 0.1bar,to reduce power consumption.

2.Variable Flow Control

The ABB frequency converter adopted is able to adjust the rotation speed of the motor in real time according to the actual air compression.In case of high air consumption,the pressure remains unchanged,but the speed compensates automatically to meet the supply needs.When the air consumption is low,pressure is maintained constant and speed is automatically reduced to supply compressed air which is just enough.

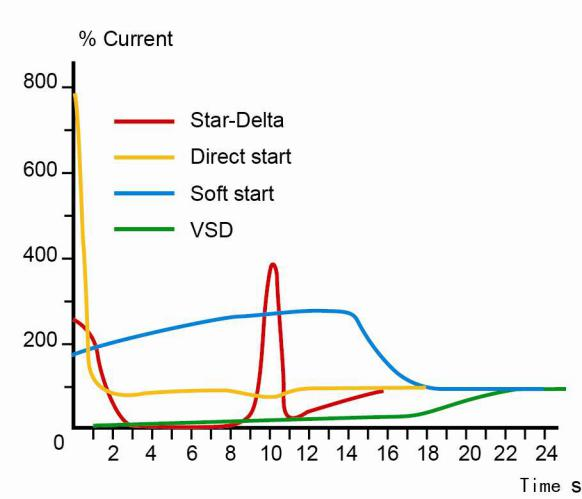

3.No Current Impact during Starting

The air compressor is started via frequency converter.The maximum starting current is 1.2 times the rated current for power frequency start.Hence,our variable speed air compressor exerts little impact on the grid during starting.It enjoys reduced stress and consequently prolonged service life.

4.High Economical Efficiency

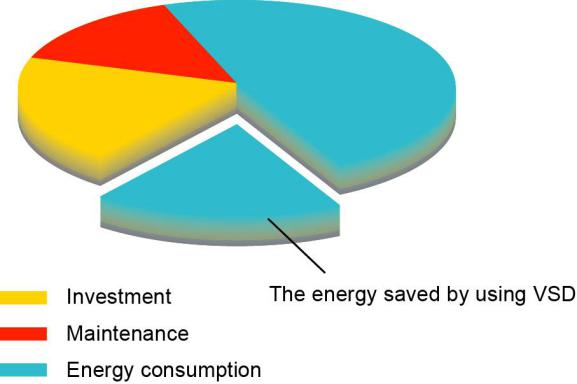

Throughout the operating life of the air compressor,energy costs account for most of all costs.However,by using s VSD,energy consumption is reduced by 30%.Therefore,the energy cost saved by a variable speed air compressor for three years is roughly equivalent to purchase price of the unit.

Main Components

Evaluation and Assessment of the saved energy

While electricity consumed by industrial air compressors accounts for a great part of a manufacturing facility’s total electricity bill, VSD air compressors can provide valuable energy saving for manufactures. However, an accurate assessment of the varying air capacity required before settling on the investment program is indispensable to getting a good return for the investment.

Stable Supply of Pressure

With the adoption of PID (proportional gain, international gain and differential gain), VSD air compressors can modulate the speed of the drive motor precisely. VSD series can also automatically track the change of the air volume, stabilize the pressure in the system and in turn reduce the electricity consumption.

Avoidance of Peak Current

Regards to VSD air compressor, peak current is avoided on starting the machine, so the damage to the power network and the whole mechanism is greatly reduced and the service life of the compressor is thus prolonged.

|

MODEL |

POWER kW |

PRESSURE bar |

AIR FLOW m3/min |

NOISEYC/ LEVEL dB(A) |

OUTLET CONNECTION |

WEIGHT KG |

DIMENSION L×W×H mm |

|

SEYC/VSD7A-8 SEYC/VSD7A-10 SEYC/VSD7A-13 |

7.5 |

8 10 13 |

0.3-1.15 0.3-1.0 0.3-0.8 |

63 |

Rp 3/4 |

220 |

1080×620×810 |

|

SEYC/VSD11A-8 SEYC/VSD11A-10 SEYC/VSD11A-13 |

11 |

8 10 13 |

0.5-1.8 0.4-1.5 0.3-1.2 |

65 |

Rp 3/4 |

260 |

1080×620×810 |

|

SEYC/VSD15A-8 SEYC/VSD15A-10 SEYC/VSD15A-13 |

15 |

8 10 13 |

0.5-2.3 0.4-2.0 0.3-1.6 |

68 |

Rp 3/4 |

430 |

775×1350×1050 |

|

SEYC/VSD18A-8 SEYC/VSD18A-10 SEYC/VSD18A-13 |

18.5 |

8 10 13 |

0.6-3.0 0.5-2.6 0.4-2.2 |

68 |

Rp 3/4 |

490 |

775×1350×1050 |

|

SEYC/VSD22A-8/D SEYC/VSD22A-10/D SEYC/VSD22A-13/D |

22 |

8 10 13 |

0.7-3.6 0.5-3.2 0.4-2.8 |

67 |

Rp 1 1/4 |

670 |

1450×860×1340 |

|

SEYC/VSD30A-8/D SEYC/VSD30A-10/D SEYC/VSD30A-13/D |

30 |

8 10 13 |

1.3-5.0 1.0-4.5 0.7-3.7 |

70 |

Rp 1 1/4 |

730 |

1450×860×1340 |

|

SEYC/VSD37A-8/D SEYC/VSD37A-10/D SEYC/VSD37A-13/D |

37 |

8 10 13 |

1.6-6.6 1.3-5.8 1.0-4.8 |

70 |

Rp 1 1/2 |

920 |

1580×950×1470 |

|

SEYC/VSD45A-8/D SEYC/VSD45A-10/D SEYC/VSD45A-13/D |

45 |

8 10 13 |

1.7-7.6 1.5-7.0 1.2-5.8 |

71 |

Rp 1 1/2 |

1020 |

1580×950×1470 |

|

SEYC/VSD55A-8/D SEYC/VSD55A-10/D SEYC/VSD55A-13/D |

55 |

8 10 13 |

2.4-10.0 2.0-9.0 1.5-7.8 |

73 |

Rp 2 |

1570 |

2000×1100×1585 |

|

SEYC/VSD75A-8/D SEYC/VSD75A-10/D SEYC/VSD75A-13/D |

75 |

8 10 13 |

3.0-13.0 2.6-11.8 2.2-9.8 |

75 |

Rp 2 |

1960 |

2000×1200×1585 |

|

SEYC/VSD90A-8/D SEYC/VSD90A-10/D SEYC/VSD90A-13/D |

90 |

8 10 13 |

3.9-15.0 3.5-13.0 2.8-11.0 |

76 |

Rp 2 |

2100 |

2000×1300×1635 |

|

SEYC/VSD110A-8 SEYC/VSD110A-10 SEYC/VSD110A-13 |

110 |

8 10 13 |

4.2-20.0 3.8-17.0 3.3-13.6 |

75 |

DN 65 |

2520 |

2166×1700×1918 |

|

SEYC/VSD132A-8 SEYC/VSD132A-10 SEYC/VSD132A-13 |

132 |

8 10 13 |

6.0-23.5 5.8-20.2 4.0-16.0 |

75 |

DN 65 |

2720 |

2166×1700×1918 |

|

SEYC/VSD160A-8 SEYC/VSD160A-10 SEYC/VSD160A-13 |

160 |

8 10 13 |

6.0-26.0 5.8-24.0 4.1-19.8 |

76 |

DN 65 |

3000 |

2466x1900x1918 |

|

SEYC/VSD180A-8 SEYC/VSD180A-10 SEYC/VSD180A-13 |

180 |

8 10 13 |

7.2-29.2 6.4-26.8 5.2-23.0 |

76 |

DN 65 |

3000 |

2466x1900x1918 |

|

SEVSD220A-8 SEVSD220A-10 SEVSD220A-13 |

220 |

8 10 13 |

10.5-36.5 8.6-33.5 7.5-28.0 |

78 |

DN 80 |

4900 |

3460x2050x2100 |

|

SEVSD250W-8 SEVSD280W-10 SEVSD315W-13 |

250 280 315 |

8 10 13 |

12.2-42.0 12.0-40.0 12.0-38.0 |

78 |

DN 100 |

6600 |

3260x2050x2100 |

|

SEVSD250A-8 SEVSD280A-10 SEVSD315A-13 |

250 280 315 |

8 10 13 |

12.2-42.0 12.0-40.0 12.0-38.0 |

78 |

DN 100 |

6600 |

3260x2050x2100 3260x2050x2100 3940x2326x2180 |

|

SEVSD280W-8 SEVSD315W-8 |

280 315 |

8 8 |

15.0-47.6 13.8-50.0 |

80 |

DN 125 |

9200 |

4580x2326x2180 |

1.Quality management and quality assurance advantages

SUCCESS ENGINE’s quality assurance systems meet the requirements of military and nuclear and were selected as military & nuclear product suppliers. For more than eigtheen years, the company has formulated quality assurance programs, quality plans, quality assurance, and personnel qualifications in accordance with Industry for National Defence Law [2005] No. 311, “Nuclear Power Plant Quality Assurance and Safety Regulations” (HAF003) and guidelines and other quality assurance procedures, design and manufacture high-level safety products.

2.First-class production environment advantage

Located in Songjiang District, Shanghai, with modern R & D and production base, beautiful environment, clean, spacious production workshop, focus on the gas source high-tech field, aims to become the leader of the compressor & fan industry, the provider of product and solution for air & gas industry.

3、Core technology advantages

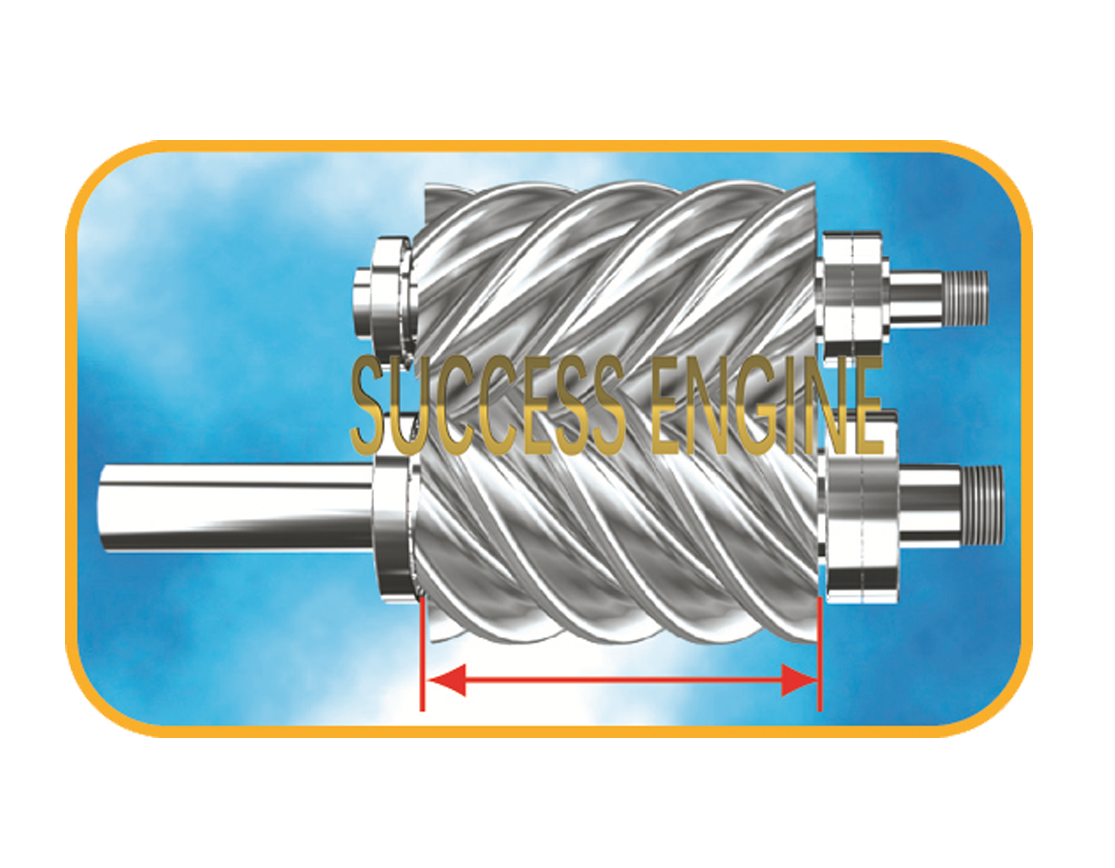

3.1、Efficiency Compressor Airend

By optimizing the bottom line of the rotor, to improve the effective volume and sealing efficiency of the compressor, making the contact line length, leakage triangle area and closed clearance volume between the three to achieve optimization, thoroughly resolving the leakage of oil and gas mixture during meshing. Design with large diameter and low speed, equipped with heavy-duty SKF bearings and three special oil seals to ensure the highest gas production efficiency and life time.

| Optimization the rotor tooth shapeThe tooth shape is a key factor affecting the efficiency of gas production. The solution to this problem lies in the technology of the shape. Through years of experience and verification, we have a plan to optimize and improve the shape of the tooth root. |  |

| Reform of the mesh and sealReform the mesh and seal of the bottom line of the rotors, reduce the problem of the leakage, and raise the volume efficiency. |  |

| Reform of lengthdiameter ratioImprove the length: diameter ratio of the double screw rotors. Raise the integral rigidity of rotors by shorten the distance between two bearings, to achieve higher volume efficiency under higher pressure, greatly decrease vibration, reduce noise, and extend the machine’s useful life. |  |

|

Optimization the rotor axial distance Increase the effective cross-sectional area of compressor rotor and the axial distance between the two shafts to maximize the utilization factor of rotor area, reserve enough space for the installation of larger diameter bearings, and fundamentally solve the failure factor of bearing wear after years. |

|

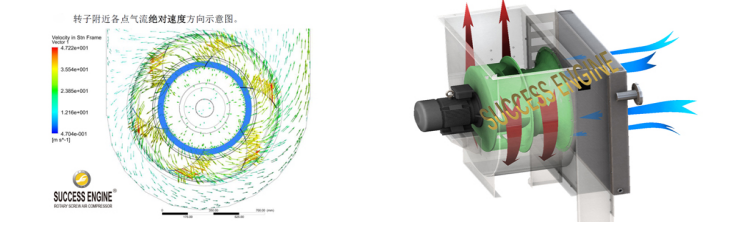

3.2、High energy-saving centrifugal cooling system (Patent No.:CN201320374179.8)

For a long time, the cooling mode of air-cooled high-power compressor mostly uses a number of common axial fans installed in the unit interior to exhaust wind outside. The fan sucks the hot air inside the unit and then cools the heat exchanger, it is difficult to achieve the best cooling effect, and therefore, air-cooled high-power units have always been a chronic disease in the air compressor industry.

SUCCESS ENGINE’s patent (a high energy-saving centrifugal cooling system) adopts the latest variable frequency centrifugal cooling structure, and uses aero-dynamics impeller ternary simulation software NUMECA to carry on the aerodynamic calculation and the full three-dimensional flow field simulation, simulates the actual operation to optimize the worm shell structure and the rotor type, to save the power, increase the dynamic pressure and achieve the optimal fan efficiency.

Independent enclosed side suction cooling structure

The aluminum plate-fin heat exchanger is installed on the suction end of the external fan of the unit to form an independent closed cooling system structure. The variable frequency speed control technology is used to automatically adjust the fan speed according to the system temperature change, change the air volume, and greatly save cooling energy consumption. It can reduce noise and completely overcome the problem of poor cooling effect of air-cooled high-power air compressor equipment.

4、High Quality Main Components

|

Air end Excellent Powerful Compressor AirendThe two pairs of rotors are independent of the two compression units, the primary compression rotor and the secondary compression rotor are combined in same compressor housing, smaller host compression ratio, less leakage, energy-saving:≧15%. |

|

PLC intelligent Touch-screen control system ◆Run Parameter ◆User parameter setting ◆Maintenance information ◆Alarm Function (Motor, Maintenance Parts)◆Controller Protection. |

|

Automatic adjustment intake value Adopting 0-100% inlet proportional intake valve which stable the work pressure and save energy. |

|

Specific VSD/PM compressor motor ◆ IP55, F Class ◆ SKF over-loading bearing ◆ Service Factor: SF=1.2 ◆ high efficient connect with inverter ◆ Voltage and Frequency can be customized |

|

High-efficiency Inverter(ABB/SUCCESS ENGINE) ◆ Automatically adjust motor speed according to real requirement, change the actual power, energy-saving more than 30% ◆ Stable pipeline pressure ◆ Eliminate peak current |

|

Control System ◆ ABB brand electrical components, including breakers, AC contactors, reliable, easy to replace ◆ MICROCHIP with Standard 485 interface, it can achieve remote monitoring according via MODBUS communication protocol ◆Collection the signals of compressor electrical , exhaust, temperature , pressure to monitor the operational status , help for quick troubleshooting. |

|

High-efficiency Filter System ◆ High-efficiency air filter, filter the air of dust and impurities, filtration come to 98.5% ◆ Branded oil filter, filter the air of oil, guarantee the long time use life of airend ◆ Oil-Air Separator element, high-efficient separation, oil contact less than 3ppm ◆ Regular maintenance notice and alarm by PLC |

|

Hight-efficiency Coupling(Direct Drive) ◆ Synchronous transmission of the airend and motor ,the efficiency come to 99% ◆ Keep the force balance, keep compressor running more stable ◆ Don’t consume the energy during the transmission |

5、Full range of products advantage

Professional R&D and manufacturing with a wide range of product categories: fixed screw air compressors, centrifugal compressors, suspension blowers, centrifugal vacuum pumps, oil-free screw air compressors, portable screw air compressors, and complete set of compressed air Processing equipment. Product specifications: flow 0.8m3/min-500m3/min, working pressure: 0.1Mpa-4.0Mpa. A complete range of types and specifications to meet various gas processing condition.

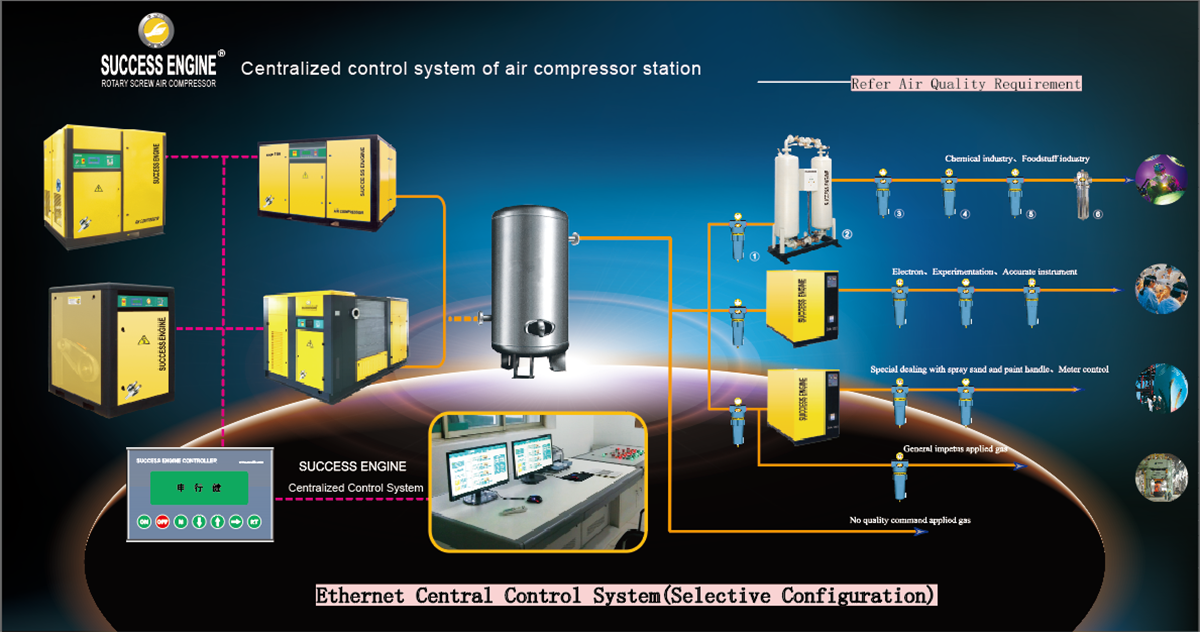

6、Multifunctional intelligent control system

Intelligent special control system, intelligent, stable, and user-friendly, can realize remote communication and management of compressed air.

①English display interface-complete functions such as automatic control, automatic protection, automatic alarm, remote control, multi-unit control, historical records, etc., to realize unattended continuous operation.

② The air volume adjustment control can be set according to the configuration conditions of the equipment, so that the air volume is automatically adjusted and energy-saving automation.

③ The exhaust pressure and exhaust temperature can be continuously monitored, displayed and controlled according to preset values.

④ Can display and process various field faults, and store and query the types and occurrence time of historical faults.

⑤ The running, loading, and unloading time can be accumulated and stored for a long time.

⑥ It can realize computer remote monitoring communication or multiple linkage switching control between air compressors.

Introduction of intelligent controller

The controllers are equipped with a 485 interface, which is used to realize two communication control modes: remote and linkage connected. The user can set the joint control of multiple units such as A, B, C, etc. according to the requirements, and manually set the starting operation sequence and timing switching time value of the unit.

Linkage control

(1) Comes with 485 port, no need to set up a joint controller.

(2) Four control modes can be set: automatic, manual, linkage control and remote.

(3) Simple cable connection can set up two or more air compressors for joint control operation.

(4) According to the pressure of the air pipe network, it is automatically judged to stop or start the standby machine for additional air supply.

(5) Timing switching, allowing the main and auxiliary machines to work alternately.

(6) Shut down by fault judgment and automatically switch the standby machine to run.

(7) Multiple machines can be connected and run alternately.