Direct-Driven Screw Air Compressor

Product Profiles

The direct driven screw air compressor transmits electric power to the airend through a flexible coupling, it consumes almost no energy in the transmit process, so that direct driven is the most efficient transmission mode.

Excellent powerful compressor airend;

This air end is equipped with latest rotors with bigger diameter and low rotate speed, SKF overloading bearing and three stages special oil seals guarantees the air efficiency and the useful lifetime, and reduce the radial vibration and air noise.

Air cooling model

Energy-saving centrifugal cooling system

Special cooling for powerful compressor (the consumption of electricity is only 7.5kw for 250kw-315kw models.

Water cooling model

High efficiency water-cooled cooler.

The element of the cooler consists of the high efficiency finned copper tube and is combined with precise shell. This combination effectively improves the heat exchange rate between compressed air and water, reduces the consumption of the cooling water.

High efficiency motor

Output efficiency is up to 96%

Degree of protection: IP55 or IP54

Service factor: SF=1.20

Special equipped SKF overloading bearing

Low noise and longtime use life

Removable Doors

With doors that can be easily removed, making servicing your compressor is quick and easy.

Advantage is our direct driven screw air compressor

1.There is no intermediate drive, so there is no energy loss.

2. Larger rotors operate at lower speeds, so it is more efficient and further reducing energy consumption.

3. It avoids some shortcomings of belt driven air compressor, such as unbalanced force, easy to generate heat, the belt is easy to break, frequent belt change, and need to re-adjust the level of the pulley and the tension of the belt frequently.

4. Due to the coaxial transmission of the flexible coupling, the force is balanced and the vibration is reduced, which increases the reliability and reduces the maintenance cost.

|

MODEL |

POWER |

PRESSURE |

AIR FLOW |

OUTLET CONNECTION |

NOISE LEVEL dB(A) |

WEIGHT (KG) |

DIMENSION (L*W*H mm) |

|||

|

KW |

HP |

BAR |

PSI |

M3/MIN |

CFM |

|||||

|

SE22A-8/D |

22 |

30 |

8 |

116 |

3.6 |

127.1 |

Rp 1 1/4 |

68 |

630 |

1300x860x1340 |

|

SE30A-8/D |

30 |

40 |

8 |

116 |

5.0 |

176.5 |

Rp 1 1/4 |

70 |

690 |

1450x860x1340 |

|

SE37A-8/D |

37 |

50 |

8 |

116 |

6.6 |

233.0 |

Rp 1 1/2 |

70 |

870 |

1580x950x1470 |

|

SE45A-8/D |

45 |

60 |

8 |

116 |

7.8 |

275.3 |

Rp 1 1/2 |

72 |

960 |

1580x950x1470 |

|

SE55A-8/D SE55A-13/D |

55 |

75 |

8 13 |

116 188.5 |

10.0 7.8 |

353 275.3 |

Rp 2 |

74 |

1460 |

2000x1100x1585 |

|

SE75A-8/D SE75A-10/D |

75 |

100 |

8 10 |

116 145 |

13.0 10.9 |

458.9 384.8 |

Rp 2 |

75 |

1580 |

2000x1200x1585 |

|

SE90A-8/D SE90A-10/D SE90A-13/D |

90 |

120 |

8 10 13 |

116 145 188.5 |

15.0 13.0 10.0 |

529.5 459 353 |

Rp 2 |

75 |

1950 |

2000x1200x1585 |

|

SE110A(W)-7/D SE110A(W)-8/D SE110A(W)-10/D SE110A(W)-13/D |

110 |

150 |

7 8 10 13 |

101.5 116 145 188.5 |

20.0 19.8 17.0 13.6 |

706 698.9 600.1 480.1 |

DN65 |

75 |

2300 |

2166x1700x1918 |

|

SE132A(W)-07/D SE132A(W)-8/D SE132A(W)-10/D SE132A(W)-13/D |

132 |

180 |

7 8 10 13 |

101.5 116 145 188.5 |

23.6 23.4 20.0 16.0 |

833.1 826.0 706 564.8 |

DN65 |

75 |

2500 |

2166x1700x1918 |

|

SE160A(W)-7/D SE160A(W)-8/D SE160A(W)-10/D SE160A(W)-13/D |

160 |

220 |

7 8 10 13 |

101.5 116 145 188.5 |

27.0 26.6 24.5 20.8 |

953.1 939.0 864.9 734.2 |

DN65 |

76 |

2750 |

2466x1900x1918 |

|

SE180A(W)-7/D SE180A(W)-8/D SE180A(W)-10/D SE180A(W)-13/D |

180 |

240 |

7 8 10 13 |

101.5 116 145 188.5 |

30.0 29.2 26.8 23.0 |

1059.0 1030.8 946.0 811.9 |

DN65 |

76 |

3000 |

2466x1900x1918 |

|

SE200A(W)-8/D SE200A(W)-10/D SE200A(W)-13/D |

200 |

270 |

8 10 13 |

116 145 188.5 |

33.6 29.5 25.0 |

1186.1 1041.4 882.5 |

DN80 |

76 |

4500 |

2966x2000x1918 |

|

SE220A(W)-8/D SE220A(W)-10/D SE220A(W)-13/D |

220 |

300 |

8 10 13 |

116 145 188.5 |

37.5 33.5 28.0 |

1323.8 1182.6 988.4 |

DN100 |

76 |

4800 |

3260x2050x2030 |

|

SE250A(W)-8/D SE280A(W)-10/D SE315A(W)-13/D |

250 280 315 |

340 380 430 |

8 10 13 |

116 145 188.5 |

43.0 42.0 40.0 |

1517.9 1482.6 1412.0 |

DN100 |

80 |

6200 |

3260x2050x2030 |

|

Air endAir end is equipped with lasted rotors with bigger diameter and low rotate speed, high –quality SKF over loading bearing and three special oil seals guarantee the high efficiency, reliability and durability. |

|

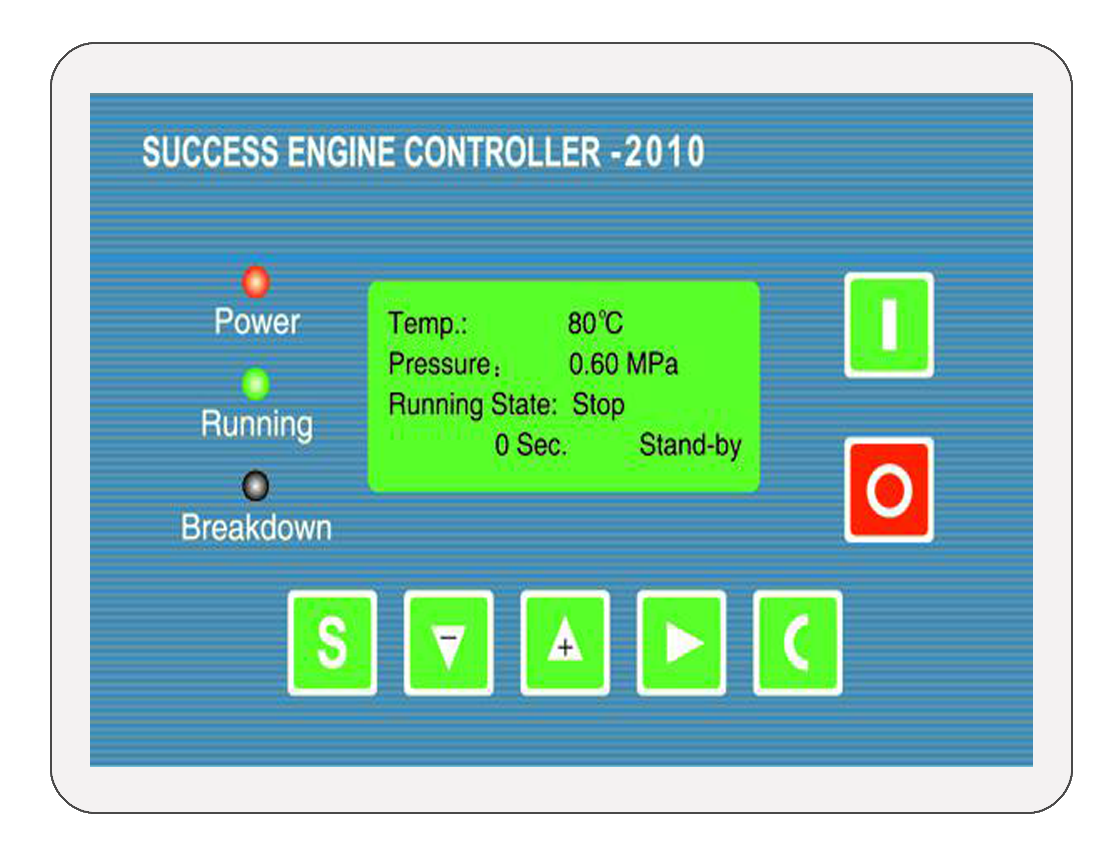

PLC intelligent control systemHuman-based Portuguese/English user interface: remote control and several compressors interconnected; running state; automatic protective alarm. |

|

Automatic adjustment intake value Adopting 0-100% inlet proportional intake valve which stable the work pressure and save energy. |

|

Specific screw compressor motor(Standard Type)◆ IP54/55, F Class◆ SKF over-loading bearing◆ Output Efficiency is up to 96%◆ Service Factor: SF=1.2◆ Low noise, long use life

◆ Voltage and Frequency can be customized |

|

High-efficiency Filter System◆ High-efficiency air filter, filter the air of dust and impurities, filtration come to 98.5%◆ Branded oil filter, filter the air of oil, guarantee the long time use life of airend◆ Oil-Air Separator element, high-efficient separation, oil contact less than 3ppm◆ Regular maintenance notice and alarm by PLC |

|

Control System◆ ABB brand electrical components, including breakers, AC contactors, reliable, easy to replace◆ MICROCHIP with Standard 485 interface, it can achieve remote monitoring according via MODBUS communication protocol◆Collection the signals of compressor electrical , exhaust, temperature , pressure to monitor the operational status , but also help for quick troubleshooting |

|

High-efficiency Cooler◆ Integrated design of air cooler and oil cooler, compacted structure, small size with lower weight◆ high- efficient heat transfer, guarantee the best cooling effect◆ Water cooling is available |

|

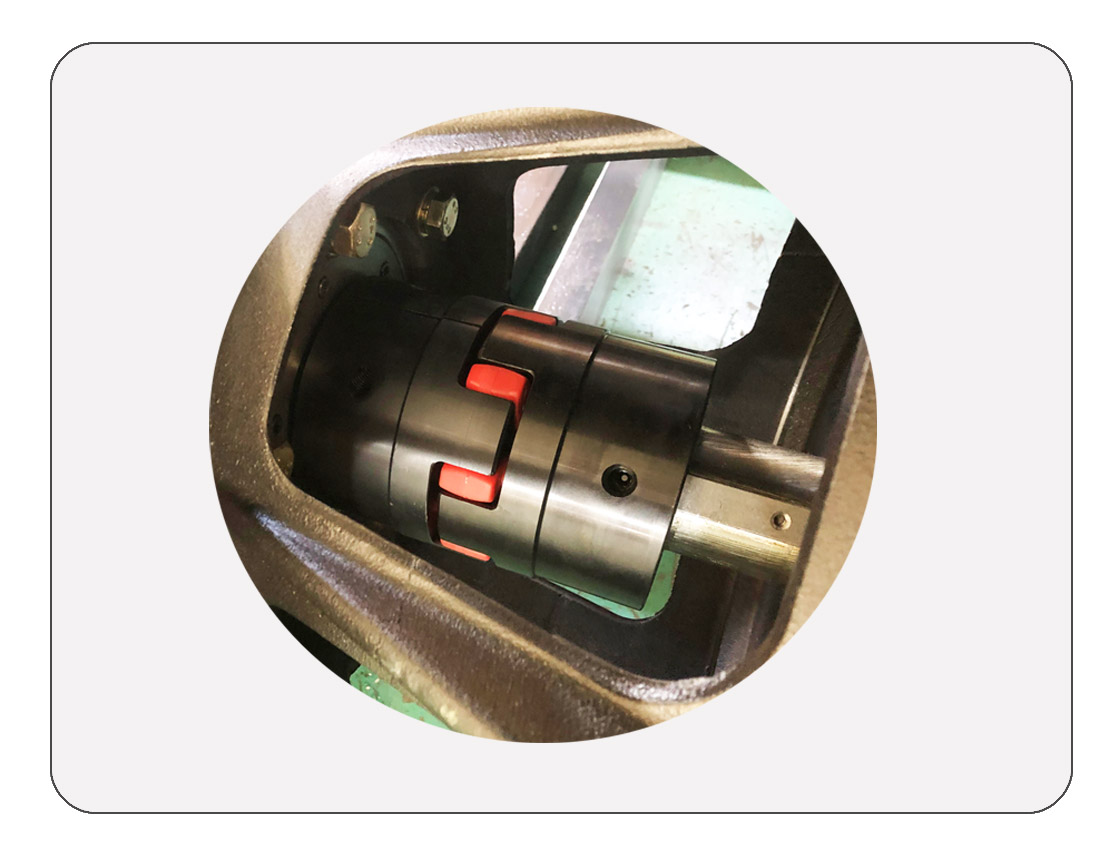

Hight-efficiency Coupling(Direct Drive)◆ Synchronous transmission of the airend and motor ,the efficiency come to 99%◆ Keep the force balance, keep compressor running more stable◆ Don’t consume the energy during the transmission |