In modern industrial operations, screw air compressors have long evolved from auxiliary equipment into a core power source that directly supports production continuity and operational safety. Whether in manufacturing, energy, or process industries, the stability of compressed air supply plays a decisive role in maintaining smooth workflows. As such, any malfunction of a screw air compressor is never an isolated equipment issue—it can interrupt production schedules, increase maintenance costs, and in certain scenarios, pose safety risks to personnel and facilities.

Based on extensive field experience and long-term operational feedback, common faults in screw air compressors typically manifest as starting difficulties, unexpected automatic shutdowns, abnormal vibrations, and temperature irregularities. These issues are often linked to factors such as improper slide valve positioning, normal wear of critical components, unstable or insufficient power supply, pipeline resonance, or inadequate lubrication and cooling conditions. While these problems may appear complex, they are usually predictable, diagnosable, and manageable when addressed early and correctly.

Effective solutions focus not only on fault elimination, but on restoring long-term reliability. This includes precise adjustment of the slide valve to ensure optimal load control, timely repair or replacement of worn components, optimization of the control and protection logic, and strict management of lubrication and cooling systems. More importantly, a systematic approach to fault analysis and preventive maintenance can significantly reduce unplanned downtime, extend equipment service life, and protect our customers’ production investments.

From our perspective, reliable compressed air is more than a technical requirement—it is a commitment to stable production, predictable costs, and operational peace of mind. By proactively understanding common fault patterns and implementing targeted solutions, we work alongside our customers to ensure that their air systems operate efficiently, safely, and consistently, even under demanding industrial conditions.

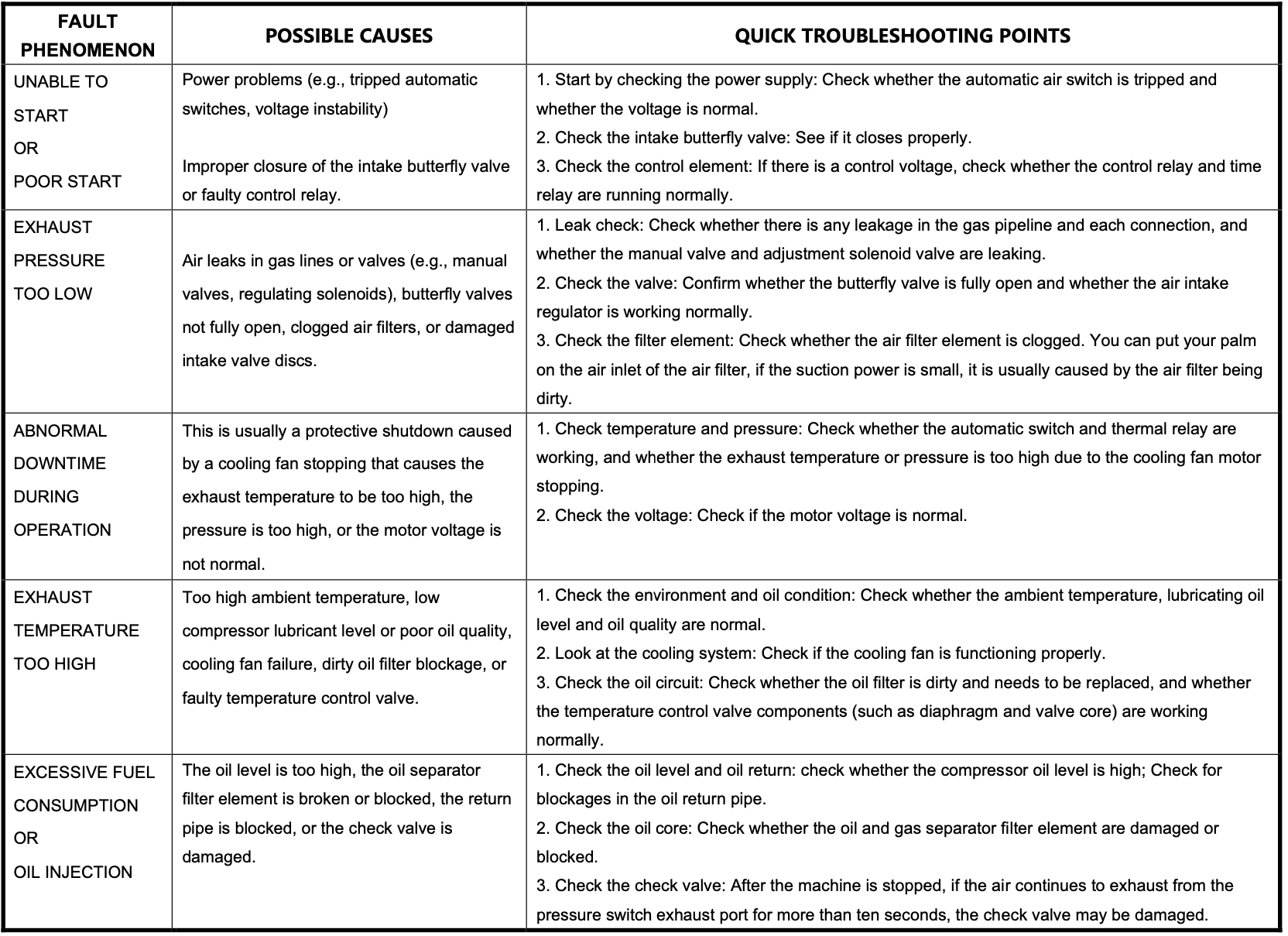

Common Fault Types, Causes, and Solutions for screw air compressor:

In the daily operation of screw air compressors, certain faults tend to occur more frequently due to long operating hours and complex working conditions. Common fault types include difficulty in starting, unexpected automatic shutdowns, abnormal vibration or noise, excessive discharge temperature, and unstable pressure output. These issues can directly affect production efficiency and, if not addressed in time, may lead to further equipment damage.

Routine Inspection and Operating Checks

Daily inspection of key operating parameters such as pressure, temperature, oil level, and running sound helps ensure the compressor is operating within normal ranges. Any abnormal readings or noises should be addressed promptly to avoid unplanned shutdowns. Consistent checks form the foundation of stable and reliable operation.

Lubrication, Cooling, and Filtration Management

Proper lubrication and efficient cooling are critical to protecting internal components and controlling operating temperature. Oil condition, cooling performance, and filter cleanliness should be checked regularly to ensure effective heat dissipation and smooth airflow. Well-maintained lubrication and filtration systems significantly extend equipment service life.

Cleaning, Tightening, and System Integrity

Keeping the compressor and surrounding area clean helps prevent dust accumulation and heat buildup. Regularly tightening bolts, fittings, and electrical connections reduces vibration and the risk of leakage or failure. Maintaining overall system integrity supports long-term reliability and safe operation.

SUCCESS ENGINE’S Product Advantages:

• High Efficiency and Energy Saving:

The optimized rotor profile and advanced tooth volume ratio are designed to maximize compression efficiency under real operating conditions, typically delivering 10%–15% measurable energy savings compared with conventional designs. An efficient cooling system combined with high-precision oil–gas separation minimizes thermal loss and internal pressure drop, helping customers reduce long-term operating costs and improve overall system efficiency.

• Stable and Reliable:

Critical components are sourced from well-established international brands, ensuring consistent quality, high durability, and extended service life. From raw material inspection to final assembly and testing, strict quality control procedures are implemented at every stage, enabling the compressor to maintain stable and reliable operation even in demanding and harsh industrial environments.

• Intelligent Control:

The compressor is equipped with an advanced intelligent control system that supports remote monitoring, automatic load adjustment, and fault diagnosis. Operators can easily access real-time operating data and receive timely fault alerts and suggested corrective actions via SMS or email, improving response speed and reducing unplanned downtime.

• Low Noise and Environmental Protection:

Advanced noise-reduction design and soundproofing materials effectively lower operating noise, creating a more comfortable working environment. High-efficiency oil–gas separation ensures low oil content in the compressed air, helping customers meet environmental regulations and air quality requirements.

Service Advantages

• Pre-Sales Professional Consultation:

Our technical team provides in-depth consultation and system analysis, offering tailored solutions based on actual operating conditions, energy targets, and application requirements to ensure the most suitable compressor configuration.

• In-Sales Installation Services:

Experienced engineers carry out on-site installation and commissioning to ensure optimal performance from the first day of operation. Comprehensive operator training is also provided to help users understand system operation, daily maintenance, and basic troubleshooting.

• Post-Sales Timely Response:

We offer 24/7 customer support, regular follow-up services, and a stable supply of original spare parts to ensure fast response and efficient repairs. This service system helps minimize downtime and protects customers’ long-term operational reliability.

Conclusion

Screw air compressor faults are complex and varied. In actual production, enterprises should prioritize maintenance and management, employing fault solutions, maintenance measures, and prevention strategies to reduce fault rates, improve operational efficiency, and ensure stable and efficient industrial production.

For more information, SUCCESS ENGINE welcomes your inquiries!

Post time: Jan-23-2026